8006 and 3003 Aluminium Foil Container Raw Material

The main food container raw materials are 8011, 3003 and 8006 aluminum foil. 3003 aluminum foil had good stamping performance while 8006 has better overall performance like better surface quality and good mechanical properties. Learn more.

The raw materials of aluminum foil for food packaging are mainly 1xxx, 3xxx and 8xxx alloy, including 1060, 1100, 3003, 8011, 8021, etc. According to the requirements of the packaged food, the degree of softness and hardness of the alloy is selected. The common tempers are H14, H16 and H18.

The food container aluminum foil is 8011 or 3003 aluminium foil. 3003 aluminum foil has good punching performance. Due to the high content of Mn element in the alloy, the grains are easy to grow during homogenization annealing. When rolling to the thickness of the finished product (0.03-0.08mm), coarse grain stripes will inevitably appear on the surface, which will affect the normal use of customers.

On the other hand, due to the characteristics of the 3003 alloy itself, the strength of the material is high, and the loss of rolling equipment and punching equipment is relatively large. At the same time, a large amount of copper and manganese metals need to be added, which increases the production cost of the aluminum foil manufacturers.

8011 aluminum foil can overcome some shortcomings of 3003 alloy, but because the content of alloy elements in 8011 alloy is low, it is soft and not suitable for high-speed punching, and the punching depth is insufficient. Its application range is limited.

Compared with 8011 aluminum foil, the tensile strength of 8006 aluminum foil is higher, which can reach 125-135. At the same time, the cupping value and elongation of 8006 aluminum foil are much higher than that of 8011 aluminum foil. More importantly, 8006 aluminum foil is produced by hot rolling process. After stamping, the edge has no wrinkles and has a beautiful appearance. It is widely used in aircraft food container in Europe.

8006 alloy contains Mn element, which is especially beneficial to the corrosion resistance of aluminum foil. 8006 alloy has better mechanical properties than 8011, 8079, and 1235 alloys. The research results show that 8006 alloy has good surface quality and extremely low number of pinholes.

8006 aluminum foil is an aluminum alloy that contains elements such as silicon, iron, manganese and copper. It has a range of advantages that make it one of the most versatile alloys. Due to its high strength, 8006 aluminum is widely used in structural applications such as automotive parts, marine components and bridges. Its strong yet lightweight properties also make 8006 aluminum ideal for engine blocks and aircraft construction.

In addition, its excellent thermal conductivity means that it is also widely used in food container, bottle cap foil,air duct foil, packaging foil, pharmaceutical foil, household foil, air conditioner foil, cable foil, cigarette foil, heat sealing foil,etc.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

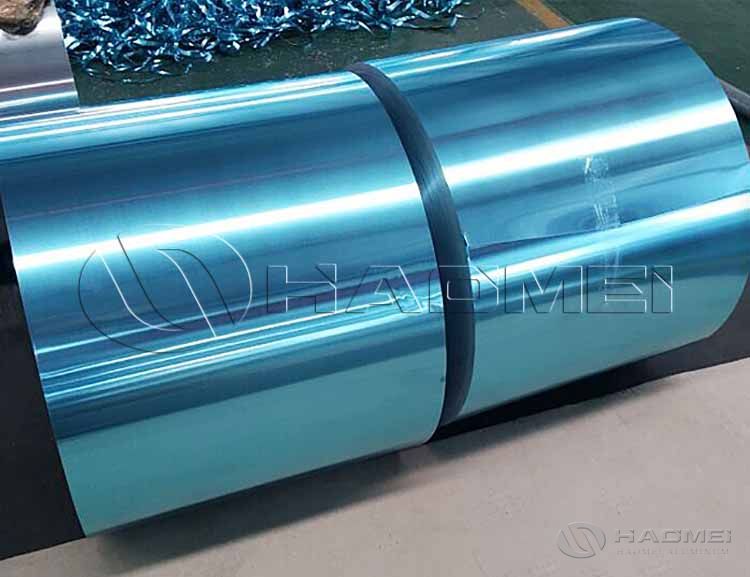

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Are Popular Uses of Aluminum Foil Alloy 1235

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

-

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

-

Different Tempers of 8011 Aluminum Foil Coil

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

-

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

-

Plain or Hydrophilic Aluminum Coil for AC

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China