Air Conditioner Aluminum Foil for Fin Stock

Air conditioner aluminum foil is for making fin stock. There are different types of aircon aluminum foil jumbo roll like plain aluminum foil, hydrophilic aluminum foil, hydrophobic aluminum foil,etc.

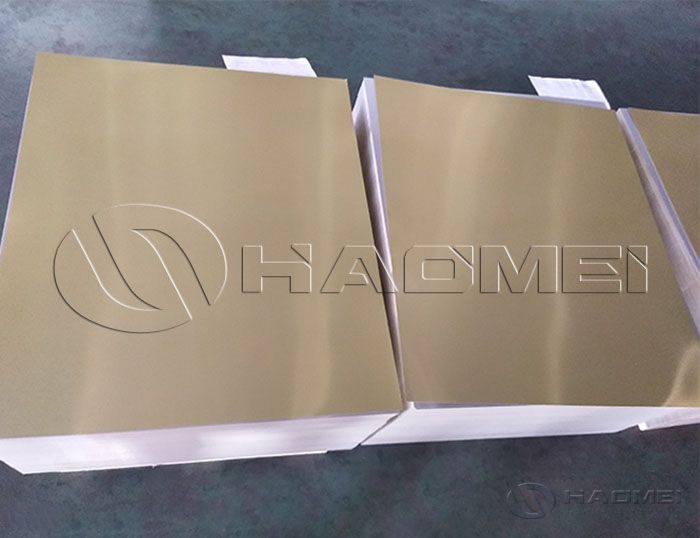

Air conditioner aluminum foil is a special material for the manufacture of heat exchanger fins for air conditioners. The aircon aluminum foil used in the early days was plain foil. It refers to aluminum foil that has been rolled and annealed without any form of surface treatment.

In order to improve the surface properties of plain foil, coated aluminum foil is to reprocess the surface of non-coated aluminum foil to make it have some special function. Different types of air conditioner foil are generated like corrosion-resistant aluminum foil, hydrophilic aluminum foil, hydrophobic aluminum foil,etc.

The surface of the corrosion-resistant aluminum foil has a certain anti-corrosion protective layer. The air-conditioning heat exchange fins made of this foil paper can be used in relatively harsh areas and can significantly improve the service life of the air conditioner.

At the same time, due to the improvement of the corrosion resistance of the heat exchange sheet, the generation of surface corrosion powder is greatly reduced, thereby improving the ventilation quality and purifying the air in the air-conditioned room.

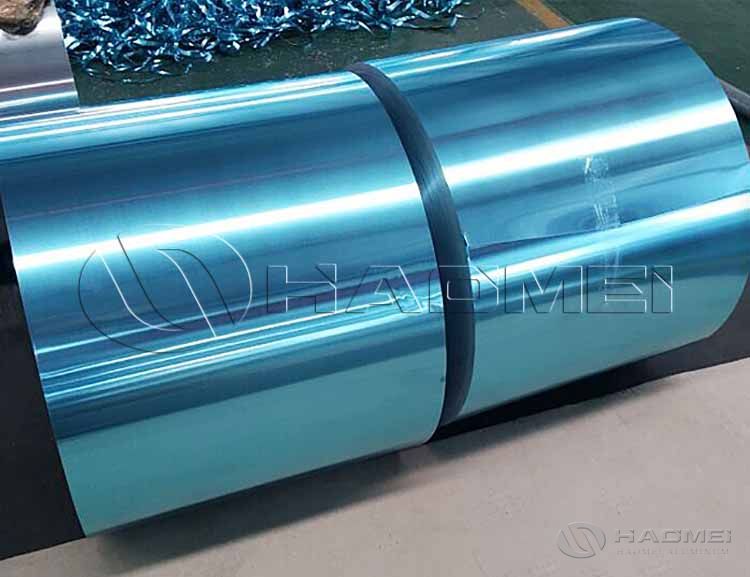

At present, hydrophilic foil accounts for 50% of the total amount of air-conditioning foil, and the proportion of its use will be further increased. Fins with good hydrophilicity can improve the heat exchange efficiency of the air conditioner heat exchanger, significantly save power consumption, and effectively reduce the distance between the fins of the heat exchanger, thereby reducing the volume of the air conditioner.

Hydrophobic aluminum foil is also called water-repellent aluminum foil, and its surface properties are just the opposite of hydrophilic aluminum foil. That is, when the condensed water condenses on the surface of the aluminum foil, the contact angle formed with the aluminum foil is relatively large, generally above 75 degrees. The larger the angle, the better the water repellency.

In the process of manufacturing the air-conditioning heat exchange fin, lubricating oil should be added to its surface first, then punching and flanging, and finally washing off the lubricating oil with trichloroethylene. Since trichloroethylene is harmful to the human body, in order to reduce this process, self-lubricating aluminum foil is produced accordingly.

The manufacturing of jumbo aluminum foil for air conditioner includes unwinding, pretreatment, surface roll coating( first roll coating → first drying → second roll coating → second drying) and coiling.

The function of pretreatment is mainly to enhance the bonding force between the coating and the aluminum foil. The function of the coating plays the role of increasing the hydrophilicity and corrosion resistance of the product. Welcome to leave message below to inquire aluminum foil jumbo roll price.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China