What Is Manufacturing Process of Colored Aluminum Foil

What is the production process of the colored aluminum foil? What should the colored aluminum foil roll factory pay attention to? It is related to the raw material and equipment. Learn more.

The main production process of printing and coating colored aluminum foil is to use an anilox roller to coat the aluminum foil with adhesive (protective agent) during the aluminum foil production process, and evenly disperse pigments or dyes of various colors into the adhesive and protective agent system,so that the adhesive layer (protective layer) on the surface of the aluminum foil presents colorful patterns.

If you want to get the correct color required by the user, you must grasp the coating amount of adhesive and protective agent during the process. This is a very important process indicator. If the configuration of adhesive protective agent is not accurate, the coating amount will vary greatly or the operation is not proper, all may cause uneven color.

In the printing process of aluminum foil, it is necessary to apply protective agent and adhesive on the surface of the aluminum foil, and evenly distribute pigments or dyes of various colors into the protective agent and adhesive system. The protective layer and adhesive layer appear in different colors, which requires certain choices of pigments or dyes.

Since aluminum foil is used for packaging medicines, disposable medical supplies and certain foods, the selected pigments must be harmless to the human body, stable in the protective layer and adhesive layer, and resistant to solvents and migration. It will not contaminate packaged medicines, medical supplies or food.

In addition, since pharmaceutical aluminum foil requires high-temperature heating during the coating, printing and blister packaging processes, the heat resistance requirements for pigments are also relatively high. Aluminum foil coating pigments are organic pigments that have been surface-treated with high molecular polymers. The principle of applying color to the surface of aluminum foil is to wrap the pigment particles with resinous polymers so that the pigment particles are in the protective layer and adhesive layer.

At present, there are four general ways to adjust the scraper pressure device in aluminum foil printing equipment: tension spring pressure adjustment, hand wheel pressure adjustment, cylinder pressure adjustment and hammer pressure adjustment. During coating, if the pressure of the scraper on the anilox roller is small, or even if the scraper does not press the anilox roller tightly or there are mechanical impurities on the blade surface, the scraper will be lifted up to form a gap, resulting in uneven coating.

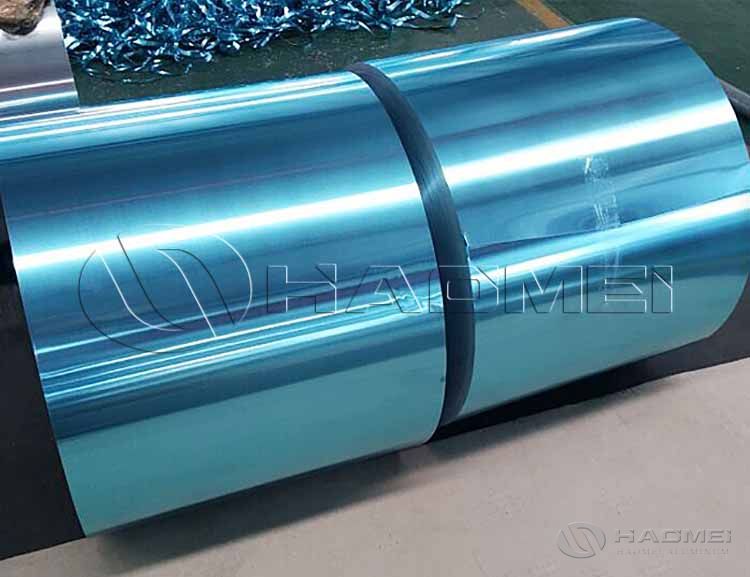

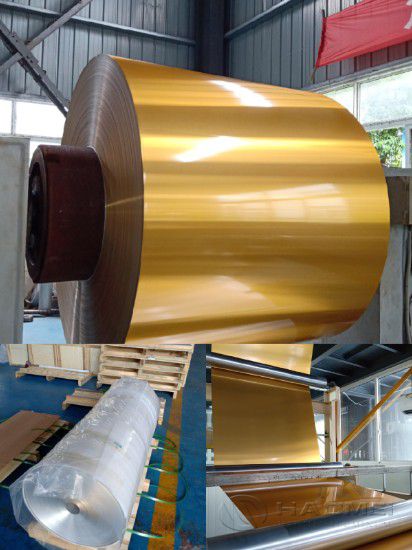

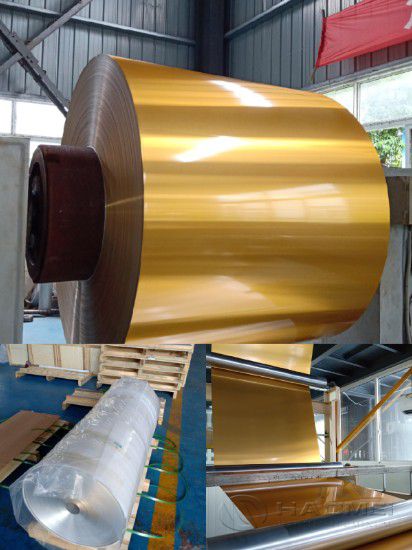

In addition to the aluminum foil jumbo roll with mill finish, Haomei Aluminum also supplies colored aluminum foil rolls for different applications. Welcome to leave message below to inquire what you need.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Aluminum Foil Specification for Food Container

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

-

2026 China Aluminum Foil Export Price Forecast

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China