What Is The Manufacturing Process of Colored Aluminum Foil

Alloy 8011 and 8021 colored aluminum foils are two popular color coated aluminum foil in packaging. What is the aluminum foil’s color coating process? What should an aluminum foil manufacturer stress? Learn more.

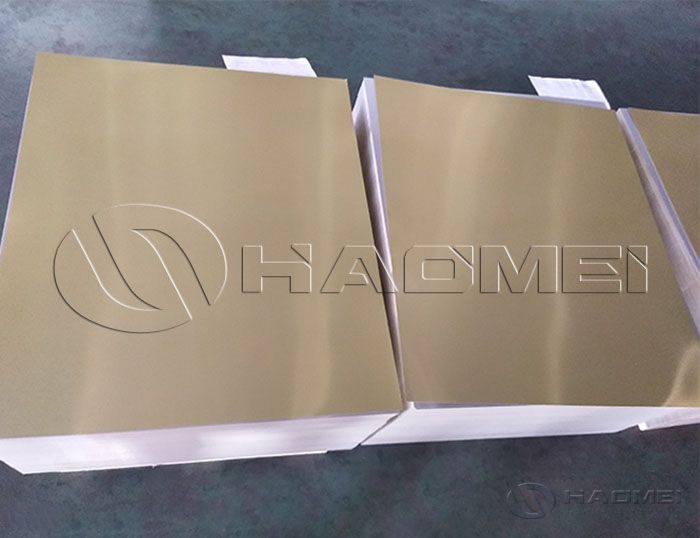

In recent years, the scope of application of aluminum foil packaging has continued to expand. In addition to pharmaceutical packaging, it is also used in food packaging, health care product packaging, etc., which has prompted the market of the colored aluminum foil. We no only have colored aluminum foil with one color like gold aluminum foil, but also has multi-color varieties with colorful text patterns. Alloy 8011 color coated aluminum foil is very popular.

Aluminum foil printing is to print text patterns through the concave surface of the printing plate roller. Firstly, the printing plate roller is processed is processed to obtain the printing plate graphics and text. The graphics and text parts are corroded into ink holes or pits on the surface of the roller's copper layer, while the non-graphic and text parts are the outer copper surface of the roller itself.

Then, the printing plate roller rotates in the ink tank, filling each ink hole with thin ink. When the roller rotates and spins out of the ink tank, the excess ink on it is removed by the scraper installed on the surface of the printing plate roller.

Finally, when the printing plate roller comes into contact with the aluminum foil as the substrate, the elastic rubber impression roller presses the aluminum foil surface against the printing plate roller, causing the ink in the ink holes to transfer to the aluminum foil surface. At this time, the aluminum foil printing work is completed.

Since aluminum foil is different from paper and plastics, the key to its printing applicability is to master the ink characteristics, ink viscosity and ink dryness in order to print products that meet quality standards and meet user satisfaction.

If you want to get the correct color required by the user, you must grasp the coating amount of adhesive and protective agent during the process. This is a very important process indicator. If the adhesive protective agent is incorrectly configured, the coating amount is greatly different, or the process operation is not standardized, it may cause uneven color and different shades of aluminum foil after coating, and poor adhesion to the plastic hard sheet, thus causing problems in the coating process.

It not only affects the appearance quality of the product, but also affects the intrinsic quality of the product. Haomei Aluminum is an experienced aluminum foil manufacturer. We can provide rich alloys of colored aluminum alloys like 8011 and 8021 aluminum foil paper.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China