Why Is Pharmaceutical Blister Foil So Popular

As an aluminum blister foil manufacturer, Haomei Aluminum tells you why the pharmaceutical blister foil is so popular. It has good barrier performance and is easy to process like printing and sealing. Learn more.

The drug issue is a major livelihood issue that concerns the lives and health of the people, and ensuring drug safety is a technical issue. At present, the forms of pharmaceutical packaging are diversified. Aluminum blister foil has good barrier properties, of which the metal crystal structure is dense, and the cleanliness is high. Therefore, PTP pharmaceutical packaging mostly uses aluminum foil as the base material.

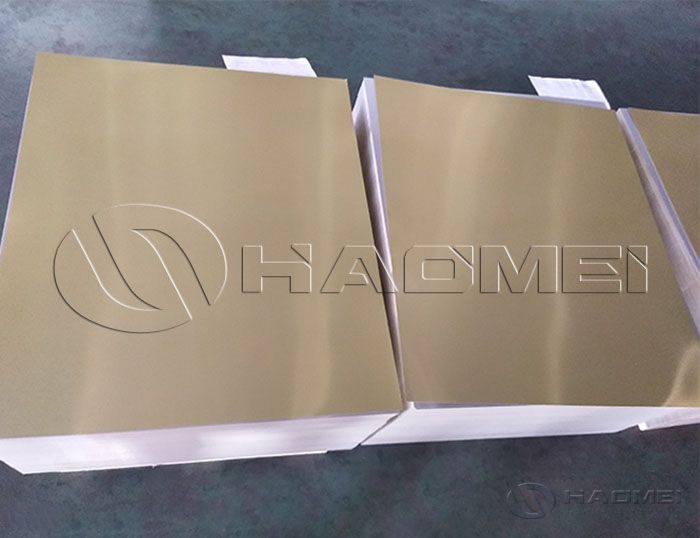

The pharmaceutical blister foil is mainly used for aluminum-plastic blister packaging of pharmaceutical tablets, capsules, pills, etc., featuring good light-shielding performance, moisture-proof performance, gas-retaining performance and taste-retaining performance. The aluminum foil is heat-sealable, printable, easy to puncture, which can be heat-sealed with PVC, PVDC and other hard plastic sheets.

Pharmaceutical PTP aluminum foil is generally made of aluminum alloy, which has excellent mechanical properties and pinhole performance, and its roughness and gloss are better than pure aluminum foil, which is conducive to high printing quality. For example, as the types of printing colors increase, the requirements for the surface quality of pharmaceutical aluminum foil are getting higher and higher.

The aluminum foil used in PTP is non-toxic and tasteless, which does not cause any harm to the human body, and has good electrical conductivity and sunshade performance. Neither metallized films nor coated special films for pharmaceuticals can completely replace aluminum foil. Aluminum foil not only has the above advantages, but also has light weight, certain strength and is very convenient to carry, so pharmaceutical companies will choose aluminum foil as drug packaging materials.

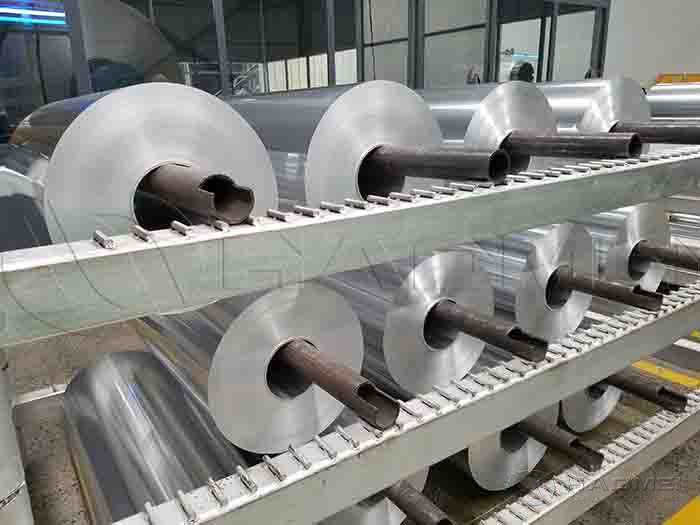

Pharmaceutical aluminum foil has a protective effect on medicines, so there are higher requirements for the control of details in each production process, such as the type of alloy selected, rolling process, pinhole, tempers, shape, surface quality and mechanical properties.

Therefore, in order to strictly ensure the quality of pharmaceutical aluminum foil, the country has strictly formulated corresponding standards, requiring relevant aluminium blister foil manufacturers to test their barrier properties, pinholes, burst resistance, etc.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Is Aluminum Foil Electrical Conductivity

In the industrial sector, the aluminum foil jumbo roll, thanks to its advantages such as lightweight, corrosion resistance, and easy processing, has become a fixture in the electronics, energy, and packaging industries. Electrical conductivity, as a

Blog

In the industrial sector, the aluminum foil jumbo roll, thanks to its advantages such as lightweight, corrosion resistance, and easy processing, has become a fixture in the electronics, energy, and packaging industries. Electrical conductivity, as a

Blog

-

What Is Specification of Aluminum Seal for Bottles

In the packaging industry, bottle sealing foil plays a crucial role, ensuring the quality of the product inside, extending its shelf life, and enhancing product safety.RequirementsGood barrier properties: This is a key characteristic of aluminum foil

Blog

In the packaging industry, bottle sealing foil plays a crucial role, ensuring the quality of the product inside, extending its shelf life, and enhancing product safety.RequirementsGood barrier properties: This is a key characteristic of aluminum foil

Blog

-

A Superstar in Packaging: Gold Wrap Aluminum Foil

On supermarket shelves, food packaging draped in gold always catches the eye instantly—the shimmering surface of chocolate boxes, the metallic sheen of tea cans, the luxurious texture of health product gift boxes—all owe their existence to the beauty of&n

Blog

On supermarket shelves, food packaging draped in gold always catches the eye instantly—the shimmering surface of chocolate boxes, the metallic sheen of tea cans, the luxurious texture of health product gift boxes—all owe their existence to the beauty of&n

Blog

-

Aluminum Foil Winding in Transformer

Among the many components of a transformer, the winding is undoubtedly one of the key components, and its performance directly affects the overall performance of the transformer.

Blog

Among the many components of a transformer, the winding is undoubtedly one of the key components, and its performance directly affects the overall performance of the transformer.

Blog

-

What Is Structure of The Cold Form Blister Packaging

In the field of packaging, cold form blister packaging stands out for its unique advantages, especially in the wide application of pharmaceutical packaging. Cold-formed blister packaging is mainly composed of two parts: the blister and the base plate

Blog

In the field of packaging, cold form blister packaging stands out for its unique advantages, especially in the wide application of pharmaceutical packaging. Cold-formed blister packaging is mainly composed of two parts: the blister and the base plate

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China