Aluminum Foil for Capacitor and Flexible Duct

Aluminum foil is widely used for electrolytic capacitors and flexible duct. What will aluminum foil bring for these two products? 8011 and 1100 aluminum foils are often used for the flexible duct. Learn more.

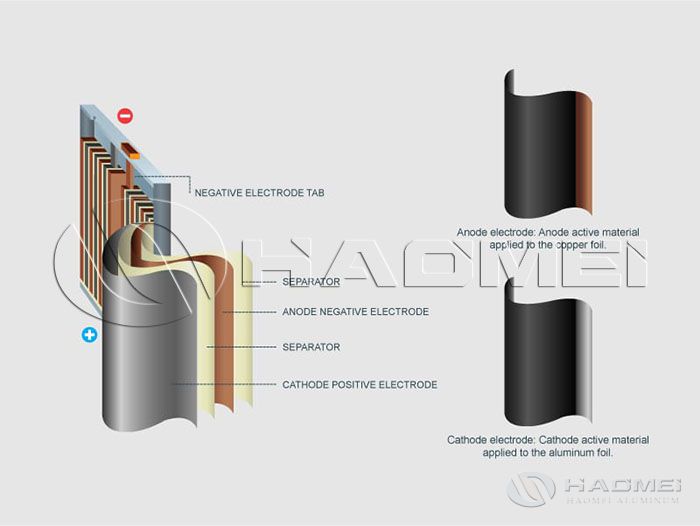

In terms of current production, aluminum electrolytic capacitors occupy the second place among capacitors. This type of capacitor was originally a general DC capacitor, but now it has developed from DC to AC. In short, the development of aluminum electrolytic capacitors is getting wider and wider.

In terms of materials, the homemade capacitor aluminum foil is very particular about its composition and structure. It is no longer required to be high purity. For example, for anode foil, its purity is required to be appropriately high. In order to improve the number of initial corrosion points, mechanical strength and the performance of the dielectric oxide film, the aluminum foil should contain certain impurities appropriately.

In terms of technology, in addition to the mechanization and automation of production, the progress of aluminum electrolytic capacitors in technology is mainly in the two processes of corrosion and empowerment. The corrosion coefficient of aluminum foil is not only very high (low-voltage capacitor foil has reached 100, and high-voltage has reached 30), but also can be corroded into aluminum foil with different pit morphologies according to the performance requirements of the capacitor.

8011 and 1100 aluminum foil jumbo rolls with H22/H18 temper are often used for the flexible duct. After embossing or coating, the gray or gold aluminum foil is compounded with phenolic board or polyurethane board, generally double-sided compound, and the finished product specifications are 20mm thick, 1200mm wide, and 4000mm long.

Compared with traditional composite ducts, phenolic aluminum foil ducts have the following advantages:

1. Super strong surface hardness. It can effectively resist collision and impact. The impact resistance is comparable to that of iron ducts, and exceeds that of inorganic fiberglass ducts, avoiding damage caused by cross-construction.

2. It is on-flammable, smokeless, and non-toxic, which is the best fire-proof smoke exhaust type duct.

3. Good insulation can greatly reduce the heat loss of air conditioners.The thermal conductivity of phenolic composite ducts is 0.016~0.036W/(m·k), while the thermal conductivity of galvanized steel ducts and FRP ducts is much higher.

4. It has strong weather resistance, which is suitable for outdoor air ducts, and can withstand long-term wind, sun and rain. Galvanized steel plates are more likely to rust in a humid environment, and fiberglass is easy to age and damage.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Price Comparison Of Different Types Of Aluminum Foils

Aluminum foil jumbo roll is a versatile metallic material used in life, industry and medicine. Learn about the price ranges of household, air conditioning and pharmaceutical-grade aluminum foil, and the key factors causing their price differences.

Blog

Aluminum foil jumbo roll is a versatile metallic material used in life, industry and medicine. Learn about the price ranges of household, air conditioning and pharmaceutical-grade aluminum foil, and the key factors causing their price differences.

Blog

-

Aluminum Foil Specification for Food Container

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

-

2026 China Aluminum Foil Export Price Forecast

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China