1050 Aluminum Foil for Battery and Electronics

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

-

Finstock and Heat Exchanger Aluminum Foil

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

In heat exchange systems used in air conditioning, automobiles, and electronic equipment, fins and heat exchangers are key components for achieving efficient temperature control. Aluminum foil, with its excellent thermal conductivity, lightweight properti

Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China

Product Introduction

Contact UsWhat is 1050 aluminum foil

1050 aluminum foil is a pure aluminum foil with 99.5% aluminum element. Since there is no need to add other chemical elements, the production process of 1050 aluminum foil is simple, and its price is relatively cheap.

Since 1050 aluminum foil is of low density, good electrical and thermal conductivity, and good corrosion resistance, 1050 aluminum foil paper is often used for battery, cable and light gauge aluminum foil.

Specification of 1050 aluminum alloy foil

Alloy | 1050 |

Temper | O,h18, h19,h24,h22,etc. |

Thickness | 0.006-0.2mm |

Width | 100-1600 mm |

Application | Food packaging, capacitors, aluminum foil gaskets, cable shielding, electronic label, container foils, etc. |

Mechanical properties

Tensile Strength σb(MPa) | Yield Strength σ0.2(MPa) | Conductivity (20℃%)(IACS,%) |

155 | >140 | 62 |

Features of 1050 Alu Foil

1. Good corrosion resistance. 1050 aluminum foil is easy to produce dense alumina passivation film on its surface in air, oxidizing aqueous solution and high-temperature concentrated nitric acid medium, so it has good corrosion resistance.

2. No low brittleness. The internal structure of 1050 aluminum foil is a cubic lattice, and there is no brittle transition at low temperature. Therefore, the lowest design temperature of the container made of 1050 aluminum foil can reach -269 ℃, which is a good choice for the material of low temperature container.

3. 1050 aluminum foil also has strong plasticity, sealing tightness, light shading, heat insulation, electrical and thermal conductivity, high ductility and reflectivity.

Applications

1. 1050 aluminum foil is suitable for container sealing of various materials such as PET, PE, PP, PVC, PS, ABS, glass, etc. It is widely used in food, medicine, cosmetics, pesticides, motor oil, detergents, hair care products, wine,etc. The common temper is H19 and the specifications are specifications are 0.2*940*1250mm and 0.2*1090*1250mm.

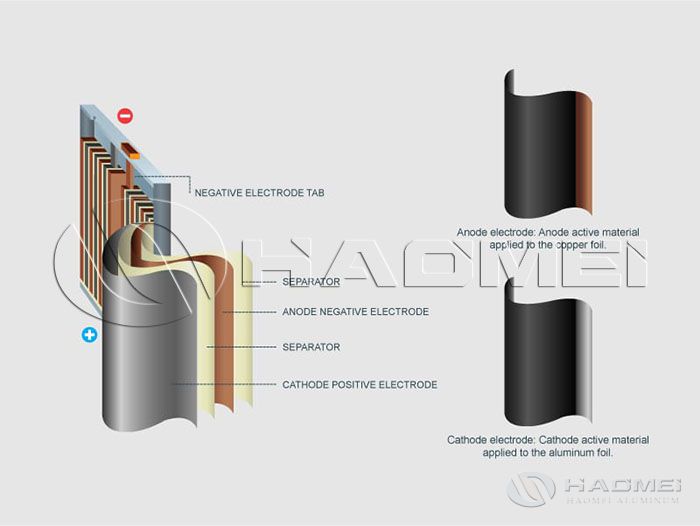

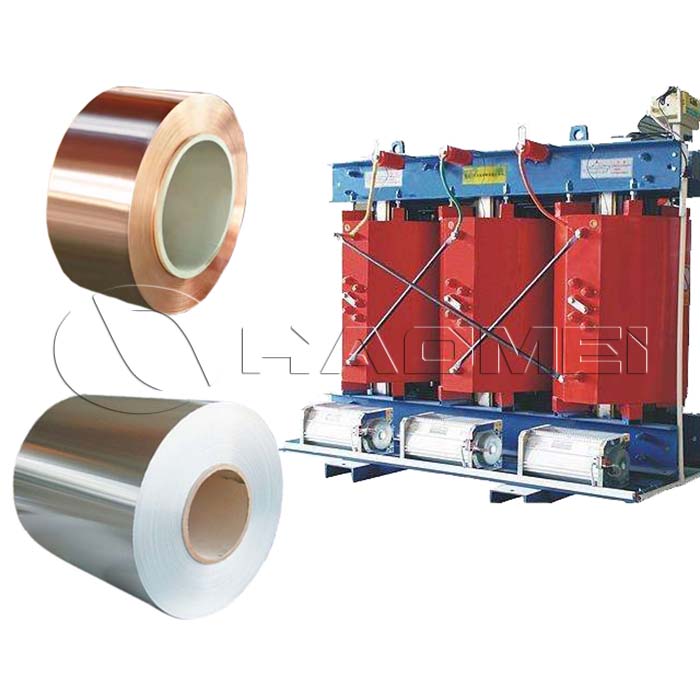

2. 1050 Alu foil is also a main kind of battery aluminum foil. Typically, the lithium-ion battery industry uses it as the positive current collector. Other battery aluminum foils are 1060, 1235, 1070, etc.

3. 1050 aluminium foil is often used as the electronic aluminum foil. The production process is casting - soaking - hot rolling - pre-annealing - cold rolling - intermediate annealing - cold rolling - foil rolling - slitting - performance testing - packaging.

4. 1050 aluminum alloy is often used as cable shielding foil. The specification is 0.2-0.5*500 mm. The number of pinholes is strictly controlled, and the product performance far exceeds the national standard.

1050 Aluminum Foil Price

Its price consists of two parts: the average closing price of Changjiang spot A00 aluminum ingot and processing fee. Since the price of aluminum ingot fluctuates daily, the quotation will fluctuate.

Why Choose Haomei

Haomei Aluminum has 8 aluminum foil rolling mills, which can produce various specifications of container foil, battery foil, aluminum foil for beer label, tape foil, medicine foil, cigarette foil with a thickness of 0.005~0.2mm and a width of 50~1700mm.

The aluminum foil rolling mills of the aluminum foil production line are equipped with Siemens pattern gauges and German Thermo Fisher thickness gauges, and are also equipped with 14 slitting machines of various sizes, 3 rewinding machines, and 3 coiling machines. , 4 roll grinders and 31 annealing furnaces.