Aluminum Foil for Dry Transformer Winding

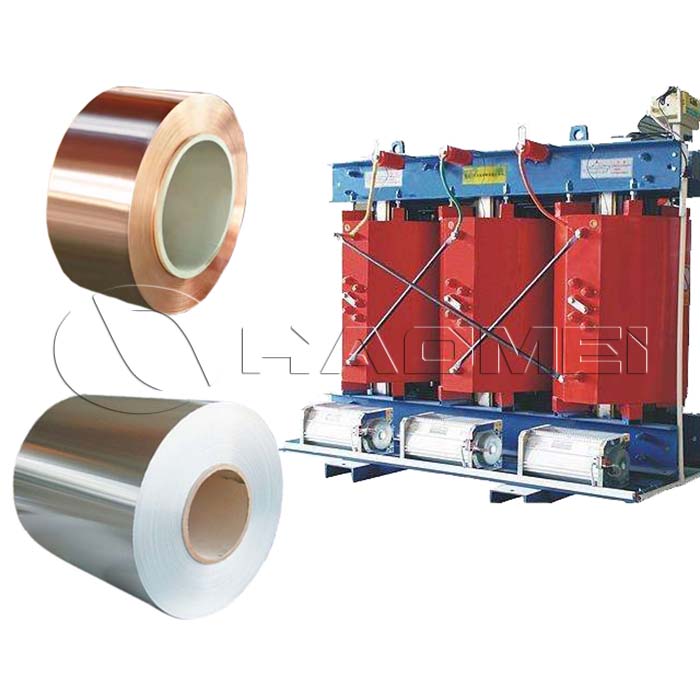

Aluminum foil for transformer is 1xxx high-purity aluminum foil. enerally the aluminum grades are 1070, 1060 and 1050 aluminum alloy. How to make dry transformer with aluminum foil? Learn more.

Dry-type transformers rely on air convection for cooling. Dry-type transformers are widely used in local lighting, high-rise buildings, airports, docks, CNC machinery and other places. Its cores and windings are not immersed in insulating oil. The cooling methods are divided into natural air cooling (AN) and forced air cooling (AF).

From an economic point of view, the economic efficiency of aluminum in transformer windings depends on the price ratio of aluminum and copper. For transformers less than 2.5 MVA, aluminum windings are more economical than copper windings. In fact, 90% of the transformer capacity in the world is less than 2.5 MVA.

Aluminum foil for transformer is 1xxx high-purity aluminum foil. Generally the aluminum grades are 1070, 1060 and 1050 aluminum alloy. The product has strict requirements on parameters such as alloy composition, conductivity,edge quality, and surface flatness. The excellent quality of aluminum foil ensures the stability of various performances of dry-type transformers and guarantees the cost-effectiveness of products after replacing copper foil.

When foil winding, the aluminum foil must be stretched to maintain a certain tension and be wound into a winding coil smoothly and flatly. The thicker the aluminum foil, the greater the tension required. The maximum tension of the foil winding machine is limited. It is dangerous to exceed the maximum tension of the machine. If the tension is too small, the wound coil will be too loose and cannot meet the size requirements.

Therefore, this is not to say that you have to increase the thickness of the 1070 aluminum foil, because transformer designers can comprehensively consider the thickness, cross-section, current density, temperature rise, etc. of the aluminum foil, rather than simply adjusting the thickness to design and calculate the winding characteristics of the transformer.

Specification:

Alloy: 1060-O, 1050, 1050A, 1070, 1070A, 1350

Application: Aluminum foil for dry-type transformers, aluminum strip for transformers

Thickness: 0.2mm--3.0mm

Width: 20mm-1650mm

Packing: wooden pallet, inner diameter 300mm or 500mm.

Resistivity is less than or equal to 0.028.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

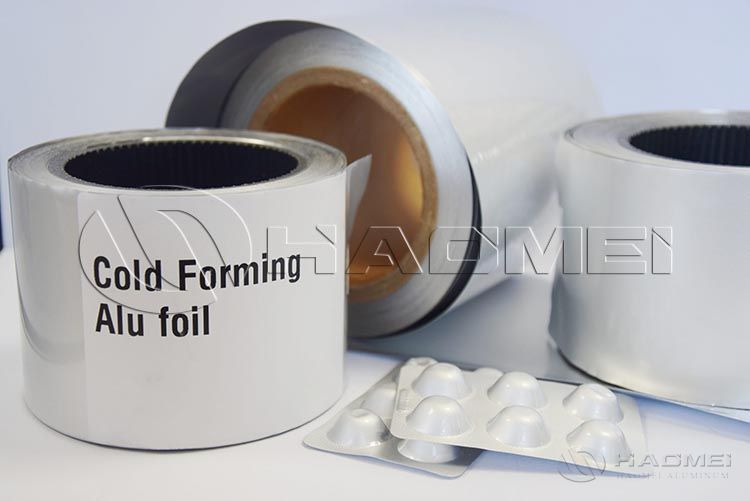

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

-

What Are Aluminum Foil Uses in the Kitchen?

Food aluminum coil is a versatile kitchen helper like baking, grilling, food preservation and cookware cleaning. How can it help you deal with kitchen problems? Learn more.

Blog

Food aluminum coil is a versatile kitchen helper like baking, grilling, food preservation and cookware cleaning. How can it help you deal with kitchen problems? Learn more.

Blog

-

Aluminum Foil for Pharmaceutical Packaging

Aluminum foil pharmaceutical packaging, with its excellent barrier properties, sealing performance, and safety, has become one of the core materials for safeguarding drug quality. From common capsule and tablet packaging to specialized ointment and p

Blog

Aluminum foil pharmaceutical packaging, with its excellent barrier properties, sealing performance, and safety, has become one of the core materials for safeguarding drug quality. From common capsule and tablet packaging to specialized ointment and p

Blog

-

Aluminum or Tin Foil for Capacitor

Among the core materials of capacitors, the choice of electrode metal foil is particularly crucial. When metal foil is mentioned, many people first think of tin foil, but in the capacitor manufacturing industry, capacitor aluminum foil has long been the a

Blog

Among the core materials of capacitors, the choice of electrode metal foil is particularly crucial. When metal foil is mentioned, many people first think of tin foil, but in the capacitor manufacturing industry, capacitor aluminum foil has long been the a

Blog

-

What Are Uses of Heavy Aluminum Foil

Heavy aluminum foil is still a thin sheet material made of aluminum and aluminum alloys through rolling. According to industry standards, aluminum foil is usually classified based on thickness: aluminum foil with a thickness of less than 0.1 mm is ca

Blog

Heavy aluminum foil is still a thin sheet material made of aluminum and aluminum alloys through rolling. According to industry standards, aluminum foil is usually classified based on thickness: aluminum foil with a thickness of less than 0.1 mm is ca

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China