Aluminum Foil Seal for Bottles

Aluminum foil seal for glass bottles is a safe and sanitary packaging. How to ensure its heat sealing performance? The surface cleanliness is very important. The residual amount of oil determines the quality of the surface cleanliness. Learn more.

Aluminum foil seal for glass bottles has many advantages: heat sealing aluminum foil s safer and healthier. The surface of aluminum foil is very clean, and any bacteria or microorganisms cannot grow and reproduce on the surface of aluminum foil without producing peculiar smell. Besides, aluminum foil is corrosion, oxidation and Acid hydrolysis resistant.

It has long storage period and is not affected by the climate environment. According to statistics, in European and American countries, aluminum foil products used for packaging account for 70% of their total demand.

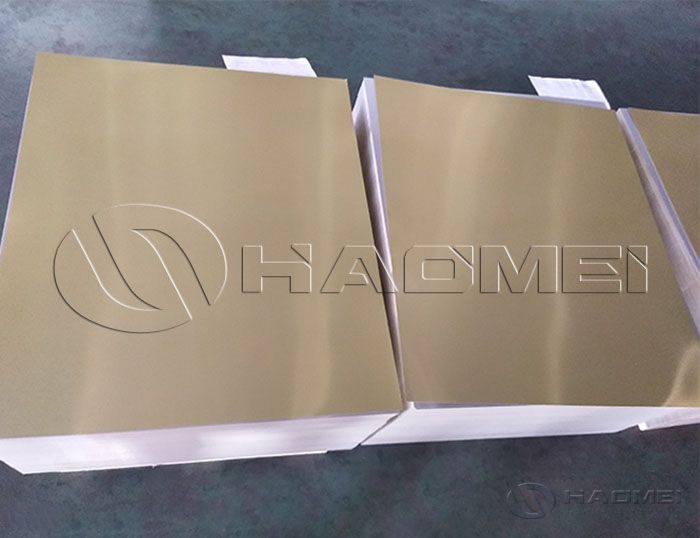

The aluminum foil for bottle cap is widely used for the sealing of polypropylene plastic bottles. Aluminum foil seal for bottles is usually composed of varnish layer or polyethylene terephthalate (PET) film, ink, aluminum foil, polyethylene film or cast polypropylene film.

Among them, the varnish layer or polyethylene terephthalate film is the outer layer, which is used as the protective layer of the sealing film to protect the ink layer in the sealing film, and the polyethylene film or cast polypropylene film is the inner layer.

As the heat-sealing layer of the sealing film, it plays a heat-sealing role. When the aluminum foil sealing film is prepared, ink is usually applied to one side of the aluminum foil, and then the varnish layer or polyethylene terephthalate is coated on the ink layer, and the other side of the aluminum foil is laminated on the polyethylene film with an adhesive.

When the aluminum foil is composited with other substrates, the surface cleanliness has a decisive influence on the composite strength. If the surface cleanliness of the aluminum foil is poor and there is oil residue, the composite strength is relatively poor.

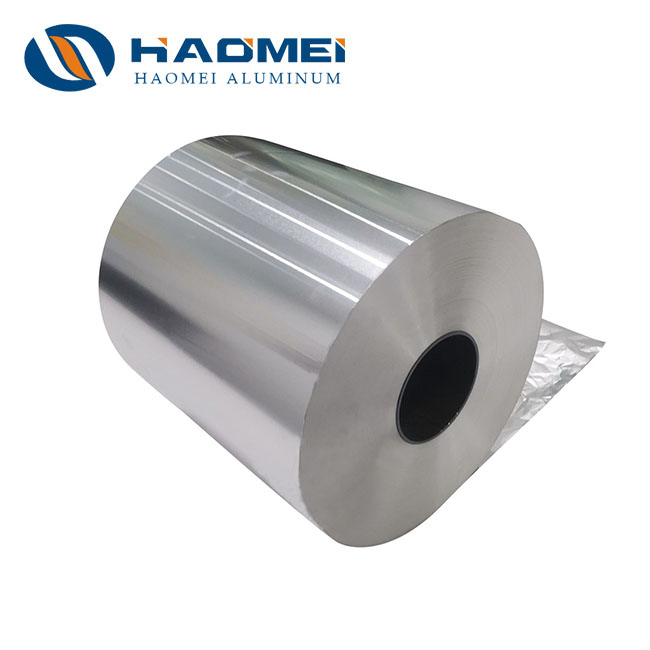

In the calendering process of aluminum foil, a large amount of lubricating oil is used, and the surface of the calendered aluminum foil should be cleaned with organic solvent acetone before winding, and the lubricating oil used during calendering should be cleaned.

The residual amount of oil determines the quality of the surface cleanliness. The surface cleanliness standard of aluminum foil is divided into five levels: A, B, C, D, and E. Among them, A level is the best cleanliness, almost no oil; B next, and so on.

Haomei Aluminum has a strict limitation of the rolling oil components. The residual amount of rolling oil on the surface of the aluminum foil is greatly reduced, and the heat sealing strength is increased from 7 to 10 MPa in the past to 20 to 24 MPa, and the heat sealing strength is significantly improved.

The intermediate annealing process adopts a slow temperature rise method, so that the temperature difference between the inner ring and the outer ring of the aluminum coil is small during the annealing process, which is not only conducive to the uniform volatilization of the surface rolling oil, but also ensures the uniformity of the mechanical properties of the aluminum foil roll. Welcome to leave message to inquire aluminum foil roll price.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Are Uses of Aluminum Foil Wrapping

Open your kitchen drawer, and that gleaming roll of aluminum foil always comes to the rescue in crucial moments—it's heat-resistant, locks in warmth, and seals out moisture. Many of our most common foods rely on it for intimate wrapping.BurgersWhether

Blog

Open your kitchen drawer, and that gleaming roll of aluminum foil always comes to the rescue in crucial moments—it's heat-resistant, locks in warmth, and seals out moisture. Many of our most common foods rely on it for intimate wrapping.BurgersWhether

Blog

-

What Is Aluminum Foil Electrical Conductivity

In the industrial sector, the aluminum foil jumbo roll, thanks to its advantages such as lightweight, corrosion resistance, and easy processing, has become a fixture in the electronics, energy, and packaging industries. Electrical conductivity, as a

Blog

In the industrial sector, the aluminum foil jumbo roll, thanks to its advantages such as lightweight, corrosion resistance, and easy processing, has become a fixture in the electronics, energy, and packaging industries. Electrical conductivity, as a

Blog

-

What Is Specification of Aluminum Seal for Bottles

In the packaging industry, bottle sealing foil plays a crucial role, ensuring the quality of the product inside, extending its shelf life, and enhancing product safety.RequirementsGood barrier properties: This is a key characteristic of aluminum foil

Blog

In the packaging industry, bottle sealing foil plays a crucial role, ensuring the quality of the product inside, extending its shelf life, and enhancing product safety.RequirementsGood barrier properties: This is a key characteristic of aluminum foil

Blog

-

A Superstar in Packaging: Gold Wrap Aluminum Foil

On supermarket shelves, food packaging draped in gold always catches the eye instantly—the shimmering surface of chocolate boxes, the metallic sheen of tea cans, the luxurious texture of health product gift boxes—all owe their existence to the beauty of&n

Blog

On supermarket shelves, food packaging draped in gold always catches the eye instantly—the shimmering surface of chocolate boxes, the metallic sheen of tea cans, the luxurious texture of health product gift boxes—all owe their existence to the beauty of&n

Blog

-

Aluminum Foil Winding in Transformer

Among the many components of a transformer, the winding is undoubtedly one of the key components, and its performance directly affects the overall performance of the transformer.

Blog

Among the many components of a transformer, the winding is undoubtedly one of the key components, and its performance directly affects the overall performance of the transformer.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China