Large Aluminum Foil Roll Wholesale Price

No matter they are consumers, manufacturer or retailers, they all hope to reduce the risk of food waste through packaging improvements and reduce the packaging materials used in each package to support the overall trend of improving resource efficiency. T

No matter they are consumers, manufacturer or retailers, they all hope to reduce the risk of food waste through packaging improvements and reduce the packaging materials used in each package to support the overall trend of improving resource efficiency. The above changes and trends have brought new opportunities for the sustainable development of aluminum foil.

There are many reasons for food waste, which are related to lifestyle and are closely related to packaging factors. Improving packaging is an important aspect in reducing food spoilage and waste. In the food supply chain, food spoilage and waste can be avoided by optimizing the packaging process.

The large foil roll has excellent barrier properties, thermal and electrical conductivity, reflectivity, etc. These physical properties bring more and better protection to the product, reduce the energy required for cooling, and extend the shelf life of the product. Protecting food from spoilage means less food waste, which requires more resources to produce than the packaging itself.

Aluminum foil packaging makes it more convenient to pack food in the right amount. Therefore, food can be prepared and consumed as needed, thus reducing waste. At the same time, it also ensures the nutritional content and health needs of the product. Smaller packaging prevents product damage and wastage compared to larger packaging, thus saving resources overall.

The research results of the European Aluminum Foil Association and the Global Aluminum Foil Producers Organization on the full life cycle carbon footprint of various foods show that the carbon emissions of aluminum foil packaging only account for a small part of the environmental impact of the entire product, generally less than 10%. These research results have been rated as the best research cases on environmental impact by the United Nations Environment Program.

Aluminum foil's exceptionally light weight and ability to be combined with other materials benefit from its many properties. Minimal materials can be used to design high-performance packaging products. Flexible packaging using aluminum foil jumbo roll has a higher product-to-package ratio than rigid packaging and can use less material space and less energy to transport.

The efficiency of aluminum foil packaging is also reflected in its ability to effectively maintain the vitamins and nutritional value of food and beverages. When the beverage was stored for 90 days, the vitamin content test results showed that the vitamin content of paper-aluminum composite packaging was 60% higher than that of PET packaging. Aluminum foil has various heating properties. Using aluminum foil packaging can shorten cooking preparation time and save energy. Welcome to leave message below to inquire the aluminum foil wholesale price.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

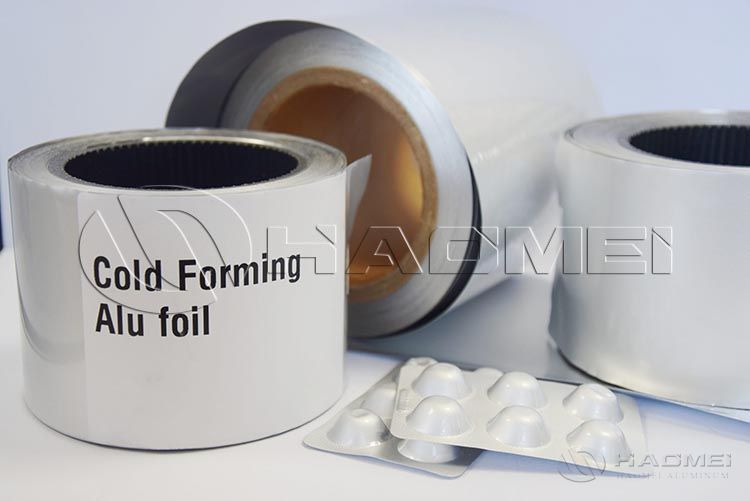

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

O Temper Aluminum Foil Vs H18 Aluminum Foil

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

In the application of aluminum foil, O temper and H18 are two extremely common material states, found in everything from food packaging and pharmaceutical blister packs to electronic components and industrial parts. Many people are confused when choo

Blog

-

Aluminum Foil for Freeze-dried Pharmaceuticals

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

Freeze-dried pharmaceuticals (FDRs) occupy an important position in biopharmaceuticals, antibiotics, and vaccines due to their advantages such as high stability, long shelf life, and convenient administration. Ensuring the quality of freeze-dried pharmace

Blog

-

Which Medicines Are Packaged in Aluminum Foil Blister Packaging

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

Aluminum foil blister packaging is often used for tablet, capsules, pills, and granules,etc. Common alloys are 8011, 8079 and 8021. What should you notice when making large purchase? Learn more.

Blog

-

What Are Aluminum Foil Uses in the Kitchen?

Food aluminum coil is a versatile kitchen helper like baking, grilling, food preservation and cookware cleaning. How can it help you deal with kitchen problems? Learn more.

Blog

Food aluminum coil is a versatile kitchen helper like baking, grilling, food preservation and cookware cleaning. How can it help you deal with kitchen problems? Learn more.

Blog

-

Aluminum Foil for Pharmaceutical Packaging

Aluminum foil pharmaceutical packaging, with its excellent barrier properties, sealing performance, and safety, has become one of the core materials for safeguarding drug quality. From common capsule and tablet packaging to specialized ointment and p

Blog

Aluminum foil pharmaceutical packaging, with its excellent barrier properties, sealing performance, and safety, has become one of the core materials for safeguarding drug quality. From common capsule and tablet packaging to specialized ointment and p

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China