The Technical Parameters of Air Conditioner Foil

The common air conditioner foil 1100, 3003, 8011, etc. What are its main technical parameters? It includes flatness, coating thickness, coating adhesion, hydrophilic properties,etc. Learn more.

The common air conditioner foils are1100, 3003, 8011, etc. What are its main technical parameters?

Flatness

The production process of coated aluminum foil requires that the aluminum foil has a good shape, which is a prerequisite for the production of coated aluminum foil. The unit for measuring the shape index is I. The general coating production equipment's requirements for the plate shape are within 20-40I. If it is greater than this value, a tension straightening system needs to be added before the coating equipment.

Coating thickness

The coating thickness on the surface of the aluminum foil is not strictly specified. Because the price of coatings is generally more expensive, the coating thickness needs to be thinner under the premise of meeting the performance requirements, thus reducing the production cost. The thickness of the coating directly affects the performance indicators of the coating, so the coating thickness on the surface of the aluminum foil is required to be uniform.

Coating adhesion

Coating adhesion is an indicator of the adhesion fastness of aluminum foil to its surface coating. If the coating adhesion is too small, the surface coating of the coated aluminum foil will easily fall off during further processing and use, which will seriously affect the weight of the coated aluminum foil. Therefore, the stronger the coating adhesion, the better.

Coating adhesion can generally only be tested qualitatively. The main testing methods include abrasion resistance test, cross-cut test and cupping method.

Hydrophilic properties

After the hydrophlic aluminum foil is used for a period of time, the hydrophilic properties of the surface will be affected by various environmental factors. Therefore, the hydrophilic performance is generally divided into the initial hydrophilicity and the hydrophilicity after the environmental resistance test.

The hydrophilic performance is determined by the angle formed by the water sticking to the surface of the aluminum foil. The initial hydrophilicity requirements of general products are a<100, and the hydrophilicity requirements after the environmental resistance test are a<250.

1. Alkali resistance test

Since the lubricating oil on the surface of the heat exchange fin after punching needs to be removed with an alkaline cleaning agent, it is required that the aircon aluminum foil must have a certain alkali resistance. The experimental conditions are generally immersed in 20% NaOH solution for 3 minutes, and then take out the experimental aluminum foil to see if the aluminum foil foams.

2. Test of heat and humidity resistance

This experiment is to test the degree of corrosion after a long time at a certain temperature and a certain humidity, so as to judge its corrosion resistance. This performance is also an important indicator to measure the weatherability of the heat exchanger fins.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

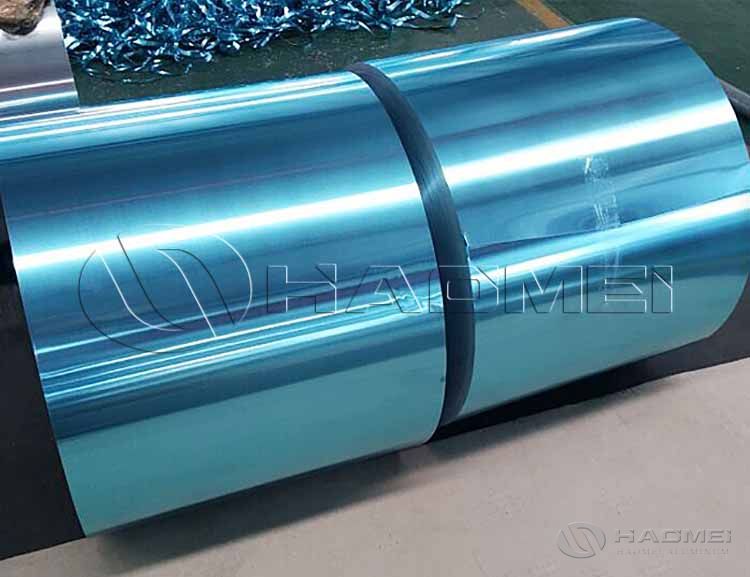

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Are Popular Uses of Aluminum Foil Alloy 1235

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

-

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

-

Different Tempers of 8011 Aluminum Foil Coil

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

-

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

-

Plain or Hydrophilic Aluminum Coil for AC

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China