Top Five Uses of The Industrial Aluminum Foil

As the "invisible material" of modern industry, industrial aluminium foil has become the core material in the fields of packaging, electronics, new energy, construction, etc., due to its light weight, corrosion resistance, high thermal conductiv

As the "invisible material" of modern industry, industrial aluminium foil has become the core material in the fields of packaging, electronics, new energy, construction, etc., due to its light weight, corrosion resistance, high thermal conductivity and recyclability.

1. Food and pharmaceutical packaging

The penetration rate of aluminum foil in the packaging field exceeds 48%, which is the main application scenario. Its ultra-thin specifications of 0.006-0.02mm, combined with alloys such as 8011 and 8021, can achieve 100% light shielding and moisture resistance, and are widely used in chocolate, coffee, and drug blister packaging. For example, after composite printing, 8021 aluminum foil can withstand high-temperature cooking at 121°C, making it the first choice for ready-to-eat food packaging.

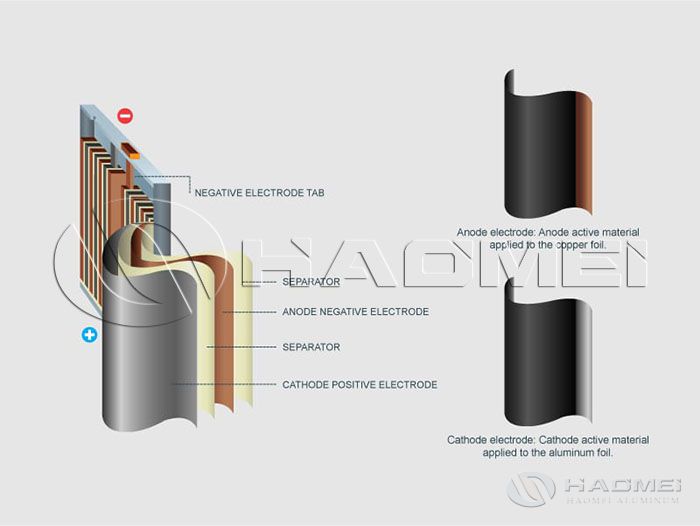

2. New energy batteries

With the explosion of new energy vehicles and energy storage industries, the demand for battery aluminum foil has increased by an average of 15% per year. As the positive electrode current collector of lithium batteries, 0.01-0.02mm 1060 and 3003 aluminum foils must meet the surface accuracy requirements of roughness ≤ 0.3μm to ensure close bonding with the electrode material. Composite aluminum foil (such as the "6μm PET+2μm aluminum layer" structure) reduces weight by 64% and increases battery energy density by 4.2%, becoming the mainstream direction of the next generation of batteries.

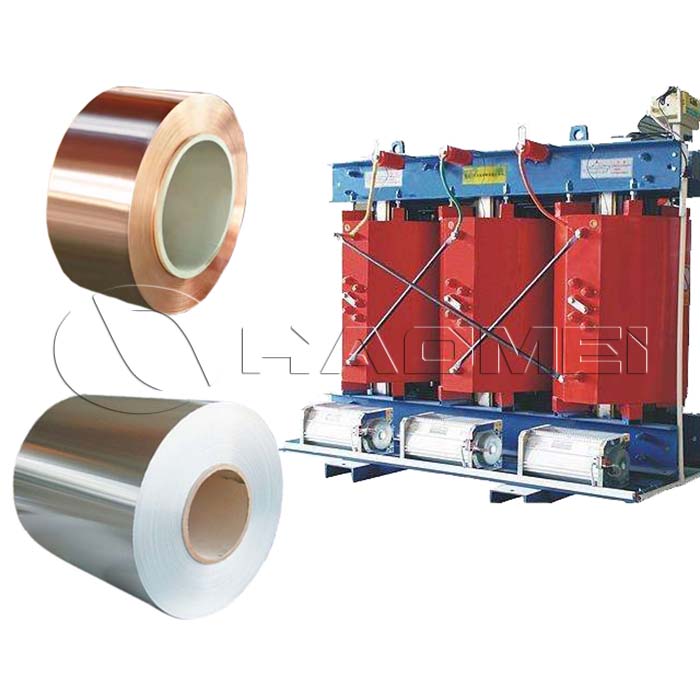

3. Electronics and electrical appliances

In the electronics field, aluminum foil is mainly used for aluminum electrolytic capacitors and radiators. After corrosion and chemical processing, 3003 and 1100 aluminum foils can be made into high-voltage anode foils with a thickness of 0.02-0.055mm and a withstand voltage of more than 450V. They are widely used in inverters and new energy vehicle electronic control systems.

Air conditioning foil (8011, 3003 alloys, thickness 0.07-0.15mm) can improve heat exchange efficiency by 15% through hydrophilic coating treatment, becoming the standard material for air conditioning heat exchangers.

4. Construction and transportation

In the construction field, 0.05-0.2mm 1060 aluminum foil and glass fiber are composited to make thermal insulation rolls with a reflectivity of 95%, which can reduce building energy consumption by 30%.

Honeycomb aluminum foil (thickness 0.08-0.2mm) is used as the core material of curtain walls, which has both sound insulation and fire resistance and has been used in super high-rise buildings such as the Shanghai Tower. In the automotive field, brazing aluminum foil (3003/4343 composite alloy) is used in radiator manufacturing, which increases heat exchange efficiency by 20% and reduces weight by 40%.

5. Special industries

In the aerospace field, 0.03-0.1mm 5052 aluminum foil is used for aircraft skins and can withstand temperature differences of -60℃ to 120℃; in the military field, aluminum foil composite materials are used for electromagnetic shielding with an attenuation rate of more than 90dB. In addition, cable foil (1235 alloy, thickness 0.12-0.2mm) can resist salt spray corrosion and ensure the life of submarine cables through plastic coating.

The length of industrial aluminum foil rolls varies significantly due to application scenarios, thickness and production processes, and is usually between 500 feet and 10,000 feet. 1000 ft aluminum foil is a common length. Welcome to inquire what you need from us.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Are Popular Uses of Aluminum Foil Alloy 1235

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

-

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

-

Different Tempers of 8011 Aluminum Foil Coil

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

-

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

-

Plain or Hydrophilic Aluminum Coil for AC

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China