What Is Cigarette Aluminum Foil Paper

The cigarette aluminum foil paper for tobacco inner lining is the most important application area of aluminum foil packaging. 1235 aluminum foil is often used for this application. How to ensure its quality? Learn more.

Aluminum foil is with a thickness less than or equal to 0.2 mm formed by rolling an aluminum or aluminum alloy coil. Aluminum foil is an aluminum product with the most processes, the most difficult processing technology, and the thinnest thickness in aluminum processing and production. It is usually machined from industrial pure aluminum. Aluminum foil production involves all rolling processes and heat treatment processes from melting casting, hot rolling, cold rolling to foil rolling.

In the field of packaging, aluminum foil is mainly used in tobacco packaging, food packaging, pharmaceutical packaging, beer labeling and daily chemical packaging. Aluminum cigarette aluminum foil paper accounts for 36% of the total packaging aluminum foil, food packaging accounts for 25%, and pharmaceutical packaging accounts for 24%. Among them, tobacco packaging is the most important application area.

1235 aluminum foil is often used for this application. Its aluminum content is more than 99.35%. It is also a kind of pure aluminum foil and is widely used in cables, adhesive tapes, and battery foils. The common temper is O and the thickness is 0.006-0.007 mm.

The tobacco foil inner lining in the cigarette pack can better prevent moisture and mildew, and keep dryness and taste. The compounding of tobacco foil adopts the wet lamination process, which has better production efficiency, economy and environmental protection than dry lamination and hot-melt lamination.

Its process is simple and thinner aluminum foil and lining paper can be used, thereby reducing the amount of raw materials and energy consumption. Its bonding speed is fast, and its bonding fastness is high, which can reduce manufacturing costs. At present, wet lamination has become the best production method of tobacco foil and has been widely promoted.

Aluminum foil jumbo roll can reach hundreds of thousands of meters, and the rolling time can be as long as about 10 hours. Errors in thickness measurement can easily occur as time goes by. The only way to adjust the thickness of aluminum foil is tension and speed. These factors have all caused the difficulty in thickness control of aluminum foil rolling.

Therefore, to really control the thickness difference of the aluminum box within 3%, many conditions are required to ensure: the use of aluminum foil blanks with qualified thickness, good control of the reduction and roll shape during rolling, stable rolling process and frequent measurement. Welcome to leave message below to inquire cigarette foil paper price.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Is Aluminum Foil Electrical Conductivity

In the industrial sector, the aluminum foil jumbo roll, thanks to its advantages such as lightweight, corrosion resistance, and easy processing, has become a fixture in the electronics, energy, and packaging industries. Electrical conductivity, as a

Blog

In the industrial sector, the aluminum foil jumbo roll, thanks to its advantages such as lightweight, corrosion resistance, and easy processing, has become a fixture in the electronics, energy, and packaging industries. Electrical conductivity, as a

Blog

-

What Is Specification of Aluminum Seal for Bottles

In the packaging industry, bottle sealing foil plays a crucial role, ensuring the quality of the product inside, extending its shelf life, and enhancing product safety.RequirementsGood barrier properties: This is a key characteristic of aluminum foil

Blog

In the packaging industry, bottle sealing foil plays a crucial role, ensuring the quality of the product inside, extending its shelf life, and enhancing product safety.RequirementsGood barrier properties: This is a key characteristic of aluminum foil

Blog

-

A Superstar in Packaging: Gold Wrap Aluminum Foil

On supermarket shelves, food packaging draped in gold always catches the eye instantly—the shimmering surface of chocolate boxes, the metallic sheen of tea cans, the luxurious texture of health product gift boxes—all owe their existence to the beauty of&n

Blog

On supermarket shelves, food packaging draped in gold always catches the eye instantly—the shimmering surface of chocolate boxes, the metallic sheen of tea cans, the luxurious texture of health product gift boxes—all owe their existence to the beauty of&n

Blog

-

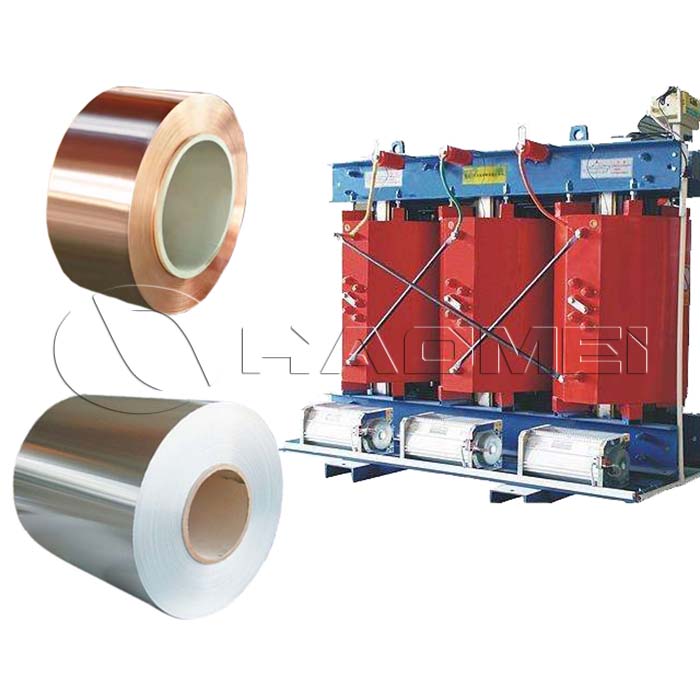

Aluminum Foil Winding in Transformer

Among the many components of a transformer, the winding is undoubtedly one of the key components, and its performance directly affects the overall performance of the transformer.

Blog

Among the many components of a transformer, the winding is undoubtedly one of the key components, and its performance directly affects the overall performance of the transformer.

Blog

-

What Is Structure of The Cold Form Blister Packaging

In the field of packaging, cold form blister packaging stands out for its unique advantages, especially in the wide application of pharmaceutical packaging. Cold-formed blister packaging is mainly composed of two parts: the blister and the base plate

Blog

In the field of packaging, cold form blister packaging stands out for its unique advantages, especially in the wide application of pharmaceutical packaging. Cold-formed blister packaging is mainly composed of two parts: the blister and the base plate

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China