What Is The Alloy Choice of Aluminium Foil Tablet Packaging

The tablet packaging can be bottle or blister packaging. The blister packaging usually chooses blister lidding foil. Haomei Aluminum provides 8011 pharma aluminum foil roll for finished products. Learn more.

The inner packaging of tablet packaging refers to the packaging that is in direct contact with the drugs, such as aluminum foil. The inner packaging should be able to ensure the quality of the drugs during production, transportation, storage and use, and be convenient for medical use. Changes in the inner packaging materials and containers of drugs should be subject to stability tests based on the materials of the selected drug packaging materials and containers to examine the compatibility of the drug packaging materials and containers with the drugs.

Compared with bottled tablets, the biggest advantage of blister packaging is that it is easy to carry and can reduce the contamination during the carrying and taking of drugs. However, as patients who take drugs regularly, there is a large single dose, which makes the unit cost of blister packaging significantly higher than that of bottled drugs. Some pharmaceutical companies usually choose blister packaging for drugs with higher prices, high technical content and new varieties.

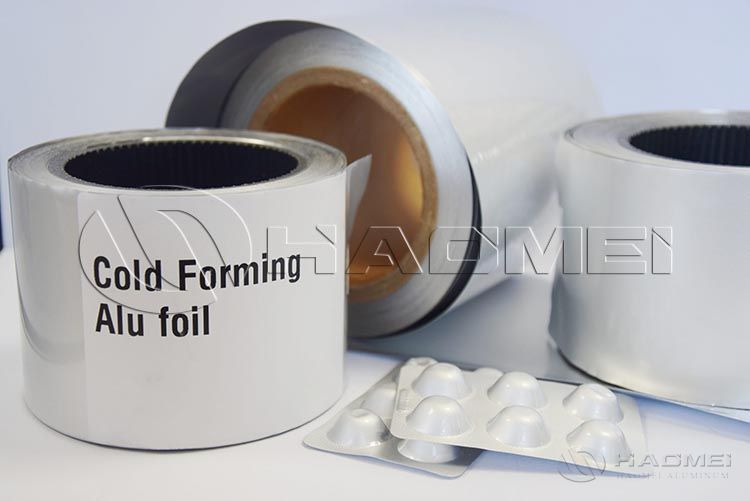

The materials used in blister packaging are mainly PTP aluminum foil and plastic hard sheets, which are mostly used to package tablets, pills and capsules. Blister lidding foil is a sealing material sealed on plastic hard sheets. It uses hard industrial pure aluminum as the base material and has the characteristics of non-toxicity, corrosion resistance, impermeability, heat resistance, moisture resistance, light resistance and high temperature sterilization. Plastic hard sheet materials usually use polyvinyl chloride (PVC), polyvinylidene chloride (PVDC) or composite materials. They have good barrier properties against water, steam and light.

On the technical level, the production of PTP aluminum foil integrates precision coating, composite processing and molding technology, and each link needs to be strictly controlled to ensure the high quality of the product. In addition, PTP aluminum foil can also be customized according to the needs of different drugs. 8011 aluminum foil is used to make PTP aluminum foil with a thickness of 0.016-0.04mm.

How to ensure PTP aluminum foil quality

First of all, PTP aluminum foil manufacturers will use high-purity aluminum alloy as the base material, usually requiring a pure aluminum content of more than 99.9% to avoid any potential contaminants affecting the quality of the medicine. High-purity aluminum alloy not only has good barrier properties, can effectively prevent oxygen, moisture and light from invading the medicine, but also ensures that no harmful substances are released during the heat sealing process, maintaining the chemical stability of the medicine.

Secondly, in order to further improve the hygiene standards of packaging, aluminum foil manufacturers will also perform special treatments on the surface of aluminum foil, such as spraying a moisture-proof layer or coating with food-grade coatings. These treatment layers also need to meet strict food hygiene standards to ensure that there is no odor and that the original properties of the medicine are not affected.

In addition, when purchasing raw materials, PTP aluminum foil manufacturers will strictly review the qualifications of suppliers and give priority to partners with international certification, good industry reputation and stable supply chain.

In summary, Haomei Aluminum has set strict raw material selection standards to not only ensure product purity, but also provide a hygienic and reliable barrier for drugs. Welcome to inquire pharma foils from it.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Aluminum Foil for Pharmaceutical Packaging

Aluminum foil pharmaceutical packaging, with its excellent barrier properties, sealing performance, and safety, has become one of the core materials for safeguarding drug quality. From common capsule and tablet packaging to specialized ointment and p

Blog

Aluminum foil pharmaceutical packaging, with its excellent barrier properties, sealing performance, and safety, has become one of the core materials for safeguarding drug quality. From common capsule and tablet packaging to specialized ointment and p

Blog

-

Aluminum or Tin Foil for Capacitor

Among the core materials of capacitors, the choice of electrode metal foil is particularly crucial. When metal foil is mentioned, many people first think of tin foil, but in the capacitor manufacturing industry, capacitor aluminum foil has long been the a

Blog

Among the core materials of capacitors, the choice of electrode metal foil is particularly crucial. When metal foil is mentioned, many people first think of tin foil, but in the capacitor manufacturing industry, capacitor aluminum foil has long been the a

Blog

-

What Are Uses of Heavy Aluminum Foil

Heavy aluminum foil is still a thin sheet material made of aluminum and aluminum alloys through rolling. According to industry standards, aluminum foil is usually classified based on thickness: aluminum foil with a thickness of less than 0.1 mm is ca

Blog

Heavy aluminum foil is still a thin sheet material made of aluminum and aluminum alloys through rolling. According to industry standards, aluminum foil is usually classified based on thickness: aluminum foil with a thickness of less than 0.1 mm is ca

Blog

-

Blister Packaging: Aluminum foil and PVDC PVC

Opening a medicine box, the pills and capsules encased in transparent "bubbles" always give a sense of reassurance; opening a snack bag, individually wrapped candies and nuts are often hidden in similar packaging. This packaging format, which co

Blog

Opening a medicine box, the pills and capsules encased in transparent "bubbles" always give a sense of reassurance; opening a snack bag, individually wrapped candies and nuts are often hidden in similar packaging. This packaging format, which co

Blog

-

Heavy Duty Aluminum Foil For BBQ

Many people think of aluminum foil as just a "wrapping tool," but in a barbecue setting, heavy duty catering foil offers much more than that; it acts as a "personal protective shield" and a "smart heat conductor" for the

Blog

Many people think of aluminum foil as just a "wrapping tool," but in a barbecue setting, heavy duty catering foil offers much more than that; it acts as a "personal protective shield" and a "smart heat conductor" for the

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China