What Is Cigarette Inner Packaging Foil

The cigarette inner packaging foil is used to preserve the fragrance and mildew. 8079 and 1235 thin gauge aluminum foils are the popular choices. How to ensure their quality? Learn more.

The cigarette inner packaging foil is mainly used as the inner lining paper of the cigarette box after being compounded with the paper. The aluminum foil paper in the cigarette case has two main functions: one is to preserve the fragrance, the other is to prevent mildew.

It is usually thin gauge aluminum foil with a thickness of 0.0063mm-0.0075mm, and aluminum foil with a thickness of 0.0055mm or less is called ultra-thin aluminum foil. The chosen alloys are 8079 and 1235 aluminum. How to ensure its surface quality?

1. Casting technology

The production of high-quality aluminium foil begins with the casting of rolled billets. Blanks are the basis for foil production and are a prerequisite for high quality and low cost. The metallurgical quality, shape and surface quality of the aluminum billet have an important impact on the production of aluminum foil.

As the thickness of aluminum foil decreases, the rolling process becomes more difficult, and the number of aluminum foil cracks, broken strips, and pinholes increases. The production of high-quality 0.005~0.006mm aluminum foil puts forward more stringent requirements for the hydrogen content of the blank, the content of non-metallic inclusions and the grain size index.

During the casting process, the optimum grain size is controlled, which has a decisive influence on the processability and surface appearance of the foil during rolling and finishing. A first-order equiaxed grain size is required.

2. Cold rolling technology

The surface of the rolled billet shall be free from cracks, scratches, metal and non-metallic indentations, oil spots and other contaminants. In order to make the surface clean, eliminate the segregation layer, and ensure the smoothness of the rolling surface, the ingot used for processing aluminum foil must be milled.

The rolling mill is equipped with an AGC thickness online measurement and adjustment system to obtain precise dimensional tolerances. The chemical composition of the aluminum foil blank must be strictly controlled within the specified range, because its changes will have a great impact on the accuracy of the X-ray thickness gauge.

3. Foil rolling technology

The rolling of aluminum foil generally starts from a cold-rolled billet with a thickness of 0.3 to 0.6 mm. After rough, medium and finish rolling to a foil of 5 to 20 μm, 5 to 6 passes are required, and the processing rate of each pass is 50 to 60%. The last pass needs to be double-rolled.

The most important aspect of aluminum foil rolling is shape control. Because the aluminum foil is very thin, if the plate shape is not good, the tension cannot be uniformly applied to the width direction during rolling, causing strip breakage, folding or wrinkling of the aluminum foil.

As a big experienced aluminum foil manufacturer, Haomei Aluminum’s 8079 and 1235 aluminum get high praise from customers worldwide. Welcome leave message below to inquire what you need.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Are Uses of Aluminum Foil Wrapping

Open your kitchen drawer, and that gleaming roll of aluminum foil always comes to the rescue in crucial moments—it's heat-resistant, locks in warmth, and seals out moisture. Many of our most common foods rely on it for intimate wrapping.BurgersWhether

Blog

Open your kitchen drawer, and that gleaming roll of aluminum foil always comes to the rescue in crucial moments—it's heat-resistant, locks in warmth, and seals out moisture. Many of our most common foods rely on it for intimate wrapping.BurgersWhether

Blog

-

What Is Aluminum Foil Electrical Conductivity

In the industrial sector, the aluminum foil jumbo roll, thanks to its advantages such as lightweight, corrosion resistance, and easy processing, has become a fixture in the electronics, energy, and packaging industries. Electrical conductivity, as a

Blog

In the industrial sector, the aluminum foil jumbo roll, thanks to its advantages such as lightweight, corrosion resistance, and easy processing, has become a fixture in the electronics, energy, and packaging industries. Electrical conductivity, as a

Blog

-

What Is Specification of Aluminum Seal for Bottles

In the packaging industry, bottle sealing foil plays a crucial role, ensuring the quality of the product inside, extending its shelf life, and enhancing product safety.RequirementsGood barrier properties: This is a key characteristic of aluminum foil

Blog

In the packaging industry, bottle sealing foil plays a crucial role, ensuring the quality of the product inside, extending its shelf life, and enhancing product safety.RequirementsGood barrier properties: This is a key characteristic of aluminum foil

Blog

-

A Superstar in Packaging: Gold Wrap Aluminum Foil

On supermarket shelves, food packaging draped in gold always catches the eye instantly—the shimmering surface of chocolate boxes, the metallic sheen of tea cans, the luxurious texture of health product gift boxes—all owe their existence to the beauty of&n

Blog

On supermarket shelves, food packaging draped in gold always catches the eye instantly—the shimmering surface of chocolate boxes, the metallic sheen of tea cans, the luxurious texture of health product gift boxes—all owe their existence to the beauty of&n

Blog

-

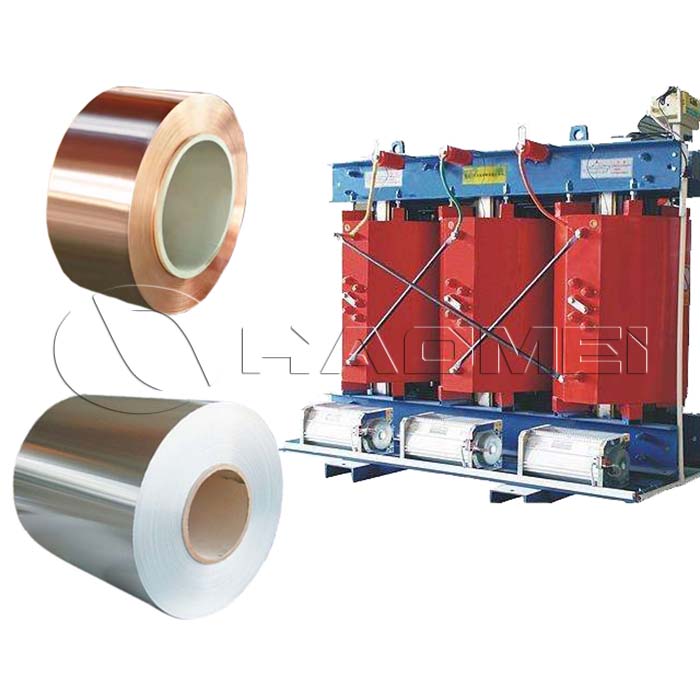

Aluminum Foil Winding in Transformer

Among the many components of a transformer, the winding is undoubtedly one of the key components, and its performance directly affects the overall performance of the transformer.

Blog

Among the many components of a transformer, the winding is undoubtedly one of the key components, and its performance directly affects the overall performance of the transformer.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China