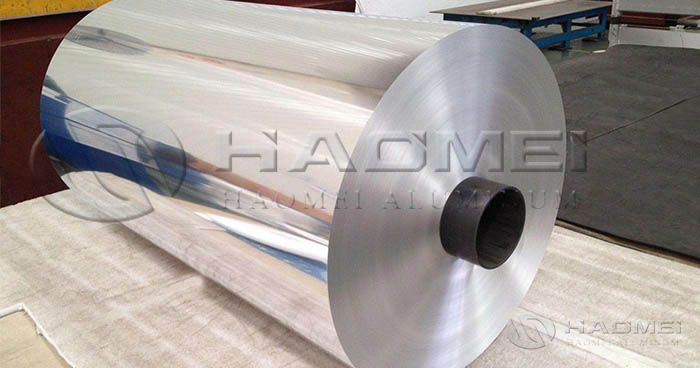

AC Outdoor Unit Aluminum Coil

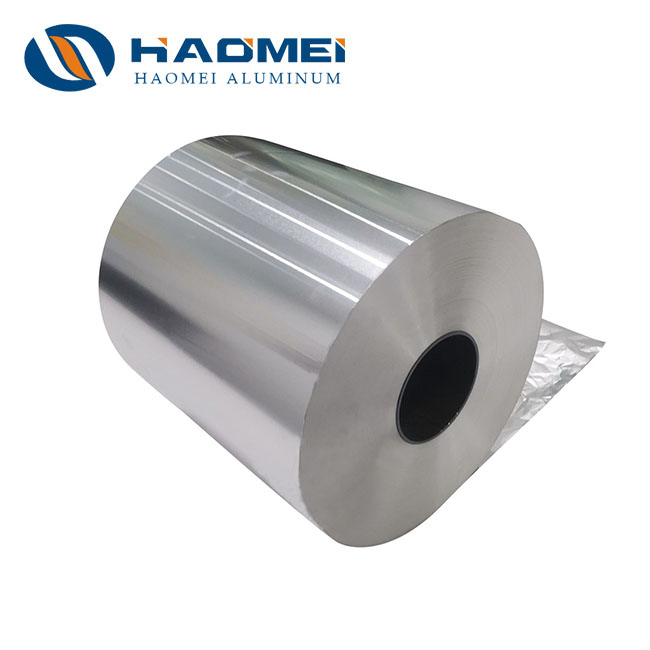

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outdoor unit's condenser and evaporator, where the choice of ac outdoor unit aluminum coil directly impacts the air conditioner's cooling and heating performance and lifespan.

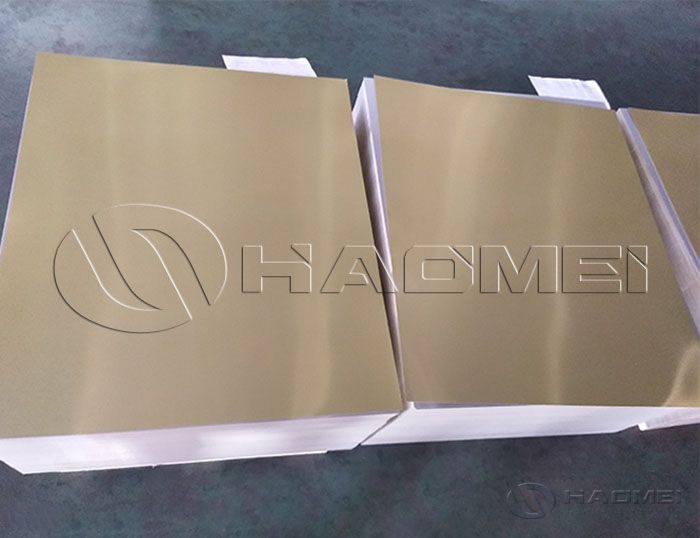

Hydrophilic aluminum foil

Hydrophilic aluminum foil is one of the most widely used types of outdoor air conditioner foil, primarily used for the condenser's heat dissipation fins. Its core feature is a special hydrophilic coating, which offers two key advantages:

Anti-condensation and anti-fouling: During cooling operation, the condenser fins are cold, and moisture in the air easily condenses on their surfaces. Water droplets on ordinary aluminum foil form "water bridges," blocking the ventilation gaps between the fins and reducing heat dissipation efficiency. Hydrophilic aluminum foil, on the other hand, allows water droplets to quickly diffuse into a thin film, sliding down the fins, preventing accumulation. This also reduces dust adhesion and minimizes performance degradation caused by dust accumulation in the outdoor unit.

Corrosion resistance and extended lifespan: Outdoor units are exposed to rain, humidity fluctuations, and contaminants for extended periods. The hydrophilic coating not only prevents moisture from coming into direct contact with the aluminum foil substrate but also protects against corrosive substances like acid rain and dust, effectively slowing oxidation and rusting, thereby extending the condenser's service life by 3-5 years.

Currently, hydrophilic aluminum foil on the market is often coated with epoxy or acrylic resin systems. Some high-end products also contain antimicrobial ingredients to further reduce mold growth, making them particularly suitable for the humid and rainy southern regions.

Anti-corrosion aluminum foil

For air conditioner outdoor units installed in harsh environments such as coastal areas and industrial areas, the corrosion resistance of ordinary hydrophilic aluminum foil may not be sufficient to withstand high levels of salt spray and pollutants. In these situations, anti-corrosion aluminum foil becomes a more suitable option. Its key difference from ordinary hydrophilic aluminum foil lies in its "double protection design":

Upgraded base material: Some anti-corrosion aluminum foils utilize an aluminum alloy base material containing elements such as magnesium and silicon. This inherently resists corrosion better than pure aluminum and can prevent salt spray from penetrating the base material.

Coating Thickening and Modification: Based on the hydrophilic coating, anti-corrosion aluminum foil increases the coating thickness (typically from the standard 5-8μm to 10-15μm), or uses a fluorocarbon modified coating. Fluorocarbon coatings are extremely chemically stable, effectively isolating the aluminum foil from chloride ions (the main component of seaside salt spray) and sulfides (pollutants from industrial areas). Even in coastal environments, they can guarantee over five years of no significant corrosion.

However, the cost of anti-corrosion aluminum foil is 15%-20% higher than that of ordinary hydrophilic aluminum foil. Therefore, it is more suitable for applications with specific corrosion protection requirements, rather than a "standard" option for ordinary home environments.

Low-Drag Aluminum Foil

In addition to its anti-corrosion and hydrophilic properties, the structural design of the aluminum foil also affects the heat dissipation efficiency of the outdoor unit. Low-drag aluminum foil is a special type that uses an optimized structure to reduce ventilation resistance and improve heat exchange. Its core design highlights lie in the fin shape:

Optimized fin profiles: While standard aluminum foil fins are mostly straight or simply corrugated, low-drag aluminum foil features "louvered," "serrated," or "wavy" fins. These profiles allow air to flow more smoothly between the fins, reducing eddies (which increase air resistance and reduce airflow). They also increase the contact area between the air and the fins, improving heat transfer efficiency.

Precise fin spacing control: Low-drag aluminum foil precisely adjusts the fin spacing (typically between 1.8-2.2mm) based on the airflow and speed of the outdoor unit's fan, avoiding excessive air resistance due to too small a spacing or insufficient heat transfer area due to too large a spacing.

Data shows that condensers using low-drag aluminum foil can improve heat dissipation efficiency by 8%-12% compared to standard aluminum foil, indirectly reducing air conditioning energy consumption. This makes it particularly suitable for energy-conscious inverter outdoor units. Welcome to inquire different types of aluminium foil from us directly.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Are Uses of Heavy Aluminum Foil

Heavy aluminum foil is still a thin sheet material made of aluminum and aluminum alloys through rolling. According to industry standards, aluminum foil is usually classified based on thickness: aluminum foil with a thickness of less than 0.1 mm is ca

Blog

Heavy aluminum foil is still a thin sheet material made of aluminum and aluminum alloys through rolling. According to industry standards, aluminum foil is usually classified based on thickness: aluminum foil with a thickness of less than 0.1 mm is ca

Blog

-

Blister Packaging: Aluminum foil and PVDC PVC

Opening a medicine box, the pills and capsules encased in transparent "bubbles" always give a sense of reassurance; opening a snack bag, individually wrapped candies and nuts are often hidden in similar packaging. This packaging format, which co

Blog

Opening a medicine box, the pills and capsules encased in transparent "bubbles" always give a sense of reassurance; opening a snack bag, individually wrapped candies and nuts are often hidden in similar packaging. This packaging format, which co

Blog

-

Heavy Duty Aluminum Foil For BBQ

Many people think of aluminum foil as just a "wrapping tool," but in a barbecue setting, heavy duty catering foil offers much more than that; it acts as a "personal protective shield" and a "smart heat conductor" for the

Blog

Many people think of aluminum foil as just a "wrapping tool," but in a barbecue setting, heavy duty catering foil offers much more than that; it acts as a "personal protective shield" and a "smart heat conductor" for the

Blog

-

Composition Purity 1050 Aluminum Foil: Aluminum content is ≥99.5%, belonging to basic high-purity pure aluminum, with no additional alloying elements added, resulting in a simpler composition. 1060 Aluminium Foil: Aluminum content is ≥

Blog

Composition Purity 1050 Aluminum Foil: Aluminum content is ≥99.5%, belonging to basic high-purity pure aluminum, with no additional alloying elements added, resulting in a simpler composition. 1060 Aluminium Foil: Aluminum content is ≥

Blog

-

The Use of Aluminum Foil in Industrial Field

Among the many materials used in industrial production, aluminum foil plays an indispensable role in several key areas due to its unique physicochemical properties.CapacitorsAs crucial components for storing charge in electronic circuits, capacitors are w

Blog

Among the many materials used in industrial production, aluminum foil plays an indispensable role in several key areas due to its unique physicochemical properties.CapacitorsAs crucial components for storing charge in electronic circuits, capacitors are w

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China