8011 Aluminum Foil Food for Packaging

Products Category

Latest Application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

-

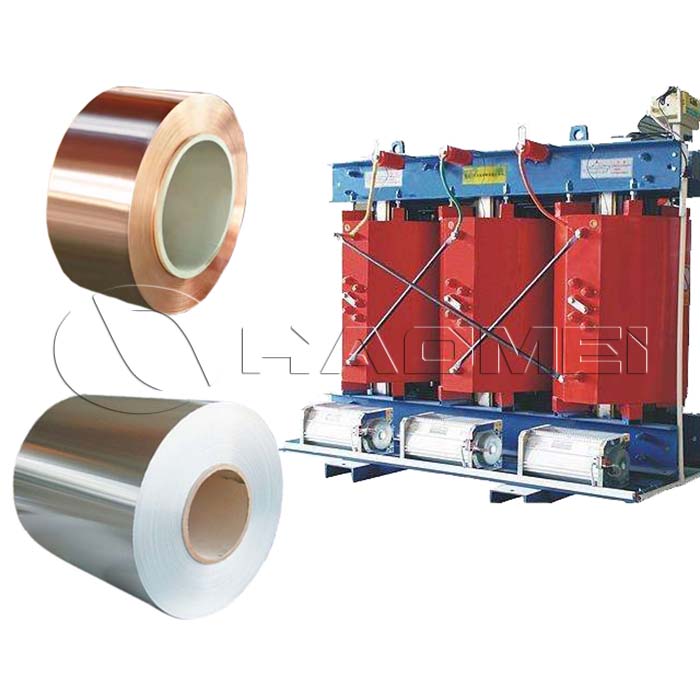

Aluminium Foil For Transformer Winding

Aluminum Foil for transformer winding is 3003, 1060, 1070 and 1050 aluminum foil. What are the advantages of pure aluminum foil for making transformer? Learn more.

application

Aluminum Foil for transformer winding is 3003, 1060, 1070 and 1050 aluminum foil. What are the advantages of pure aluminum foil for making transformer? Learn more.

application

-

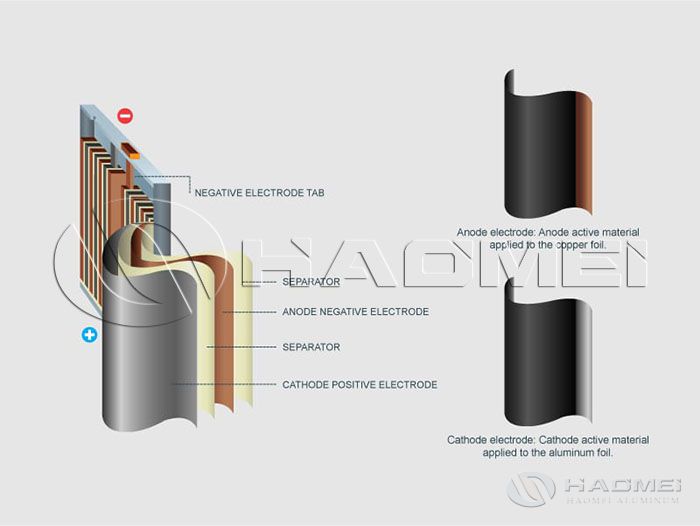

Aluminum Foil Battery for Sale

Aluminum foil battery is is used as a current collector for lithium-ion batteries. Haomei offers 1235/ 1050/1060/1070/1100 aluminum foil for you. Learn more.

application

Aluminum foil battery is is used as a current collector for lithium-ion batteries. Haomei offers 1235/ 1050/1060/1070/1100 aluminum foil for you. Learn more.

application

-

Aluminum Foil Paper for Cigarette Packaging

The aluminum foil thickness for cigarette packaging is 0.006mm to 0.007mm. The common alloys are 8011 and 8079. Learn more.

application

The aluminum foil thickness for cigarette packaging is 0.006mm to 0.007mm. The common alloys are 8011 and 8079. Learn more.

application

Latest Blog

-

What Is Structure of The Cold Form Blister Packaging

In the field of packaging, cold form blister packaging stands out for its unique advantages, especially in the wide application of pharmaceutical packaging. Cold-formed blister packaging is mainly composed of two parts: the blister and the base plate

Blog

In the field of packaging, cold form blister packaging stands out for its unique advantages, especially in the wide application of pharmaceutical packaging. Cold-formed blister packaging is mainly composed of two parts: the blister and the base plate

Blog

-

In modern life, air conditioners have become an indispensable household appliance, creating a comfortable indoor environment for people. Aircon aluminum foil plays a vital role behind the efficient operation of air conditioners. Aluminum foil, with i

Blog

In modern life, air conditioners have become an indispensable household appliance, creating a comfortable indoor environment for people. Aircon aluminum foil plays a vital role behind the efficient operation of air conditioners. Aluminum foil, with i

Blog

-

Is Aluminum Foil Biodegradable

In today's era of increasing environmental awareness, we are increasingly concerned about the sustainability of the materials we use in daily life. Can aluminum foil, a material commonly used in kitchens, food packaging and industrial applications, be

Blog

In today's era of increasing environmental awareness, we are increasingly concerned about the sustainability of the materials we use in daily life. Can aluminum foil, a material commonly used in kitchens, food packaging and industrial applications, be

Blog

-

What Are 8011 Aluminium Foil Applications?

8011 aluminum foil is a metal foil made of aluminum as the main raw material through a series of rolling processes. With good formability, barrier properties and economic cost advantages, it has been widely used in packaging, air conditioning, household a

Blog

8011 aluminum foil is a metal foil made of aluminum as the main raw material through a series of rolling processes. With good formability, barrier properties and economic cost advantages, it has been widely used in packaging, air conditioning, household a

Blog

-

In the field of aluminum processing, the two pure aluminum foils 1100 and 1235 have formed differentiated application scenarios with their different composition designs and process characteristics.1. The essential difference between alloy composition and

Blog

In the field of aluminum processing, the two pure aluminum foils 1100 and 1235 have formed differentiated application scenarios with their different composition designs and process characteristics.1. The essential difference between alloy composition and

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China

Product Introduction

Contact UsWhat is 8011 aluminum foil

8011 aluminum foil paper is a main kind of food aluminum foils. Its si (silicon) content is between 0.5-0.8%, fe (iron) content is between 0.6-0.9%, and there are trace elements. It is mainly used in pharmaceutical packaging, food packaging, cable foil, milk capping material, sealing foil and other fields.

Haomei Aluminum can offer 8011 aluminum foil with a thickness of 0.018-0.5 mm. It has excellent mechanical properties such as product elongation and tensile strength, and stable quality.

Specification of aluminum packaging foil

Alloy | 8011 |

Temper | O,H14,H16,H18,H19,H22,H24 |

Thickness(mm) | 0.018-0.2 |

Width(mm) | 100-1600 |

Application | Medicine foil, tape foil, cable foil, food container foil, food packaging foil, etc. |

Features

1. Its hardness is between H14-H24, the tensile strength is between 110-320, the elongation is generally not less than 4. 8011 aluminum foil grade can reach A grade and is of extremely low ear rate, which an meet special requirements such as high temperature cooking and sterilization.

2. It is of clean surface without spots and pinholes.

3. It is not toxic, asteless, safe and hygienic.

4. It has excellent moisture resistance and high barrier ability.

5. It has strong mechanical properties, high blast resistance, puncture resistance and tear resistance.

6. It has good corrosion resistance and certain ability of stress corrosion cracking.

Applications

1. 8011 aluminum foil for bottle cap: white wine bottle caps, red wine bottle caps, cosmetic bottle caps, milk powder caps, medicine caps, beverage caps, yogurt caps, etc.

2. 8011 aluminum foil for pharmaceutical packaging: PTP pharmaceutical aluminum foil, cold stamping pharmaceutical foil, 8011-H18 pharmaceutical packaging aluminum foil, capsule aluminum foil,etc.

3. 8011 aluminum foil packaging: food packaging, heat sealing foil, container foil, aluminum foil gasket for sealing,etc.

4. 8011 industrial aluminum foil: aluminum foil for transformer, aluminum foil tape, aluminum foil for cable tape, aluminum foil for filter, aluminium foil for air conditioner,etc.

8011 Aluminium foil VS other alloys

The purity of 8011 aluminum foil is not as high as that of 1050. In addition, 1050 alloy is softer than 8011 alloy, with lower work hardening rate and lower tensile strength. In terms of use, 8011 aluminum foil is often used as beer foil, household foil, air conditioner foil, etc.; 1050 aluminum foil is often used in electronics foil, cable foil and battery foil.

8011-H18 aluminum foil is often used for pharmaceutical packaging after being glued, coated with plastic wrap and printed; 1235 aluminum foil is commonly used in tape foil, cable foil, battery foil, bottle cap material, etc.

Why Choose Haomei

Haomei Aluminum m supplies 1/3/5/8 series of aluminum foil products, which can implement many standards such as national standard, American standard, European standard, Russian standard, etc. to meet your diverse needs.

In addition, with reliable raw material supplier, its own power plant,a large factory of 1.3 million square meters, large-scale production, we can give you a best price due to the relatively low production cost.

How to choose aluminum foil supplier

1. Aluminum foil quality. A reliable aluminum foil manufacturer should ensure excellent product quality and superior performance. Haomei food-grade aluminum foil can achieve good surface, uniform gloss, no error in product thickness, accurate specifications, and no bright spots and bright marks.

2. Aluminum foil factory. Production scale, annual production capacity, equipment strength, and market reputation are important factors for choosing a long-term aluminum foil supplier. Haomei Aluminum has 4 major production bases, advanced foil rolling mills, strict 6S supervision system, skilled production technology, and rich processing experience.

3. Afte-sale service. For every order, from pre-sale consultation to after-sale delivery, we track in time and provide considerate after-sale service.