Coated Aluminum Foil for Aircon

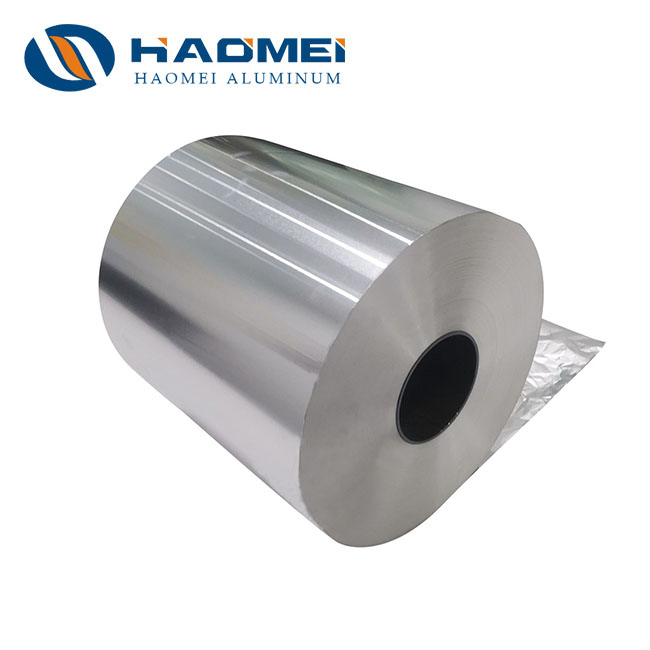

The aluminum foil for aircon has two types:plain aluminum foil and coated aluminum foil. One of the main coated aluminum foil is hydrophilic aluminum foil. What are its properties?

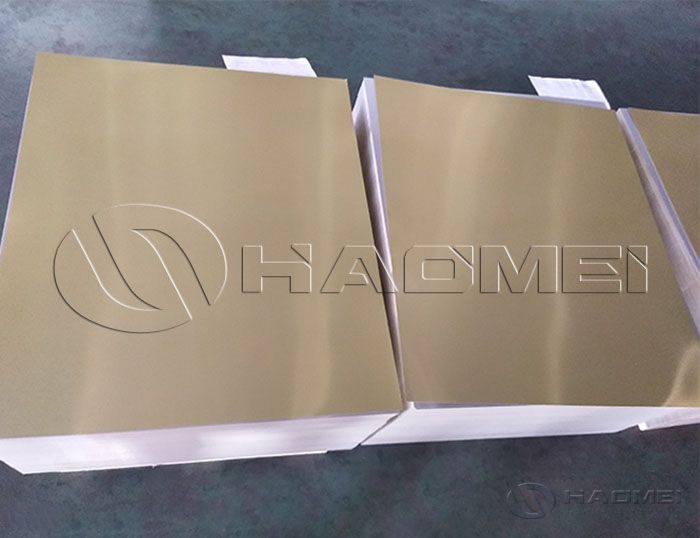

Aircon aluminum foil is a special material for the manufacture of heat exchanger fins for air conditioners. The air-conditioning foil used in the early days was plain foil. Uncoated aluminum foil refers to aluminum foil that has been rolled and annealed without any form of surface treatment.

To In order to improve the surface properties of plain foil, coated aluminum foil is to reprocess the surface of non-coated aluminum foil to make it have some special function. In countries with rapid technological development such as Japan and Germany, coated aluminum foil has been used for more than 15 years.

The production process of coated aluminum foil requires the aluminum foil to have a good shape, which is a prerequisite for the production of coated aluminum foil. The unit for measuring the shape index is I. The general coating production equipment's requirements for the plate shape are within 20-40I. If it is greater than this value, a tension straightening system needs to be added before the coating equipment.

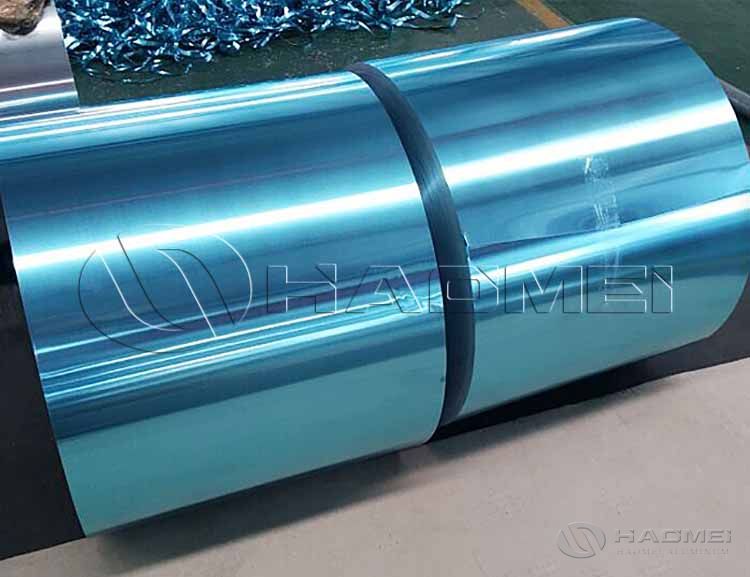

Hydrophilic aluminum foil is one of the main coated aluminum foils. It is a hydrophilic treatment of aluminum foil. The aluminum foil for air conditioners with a thickness of about 0.1mm is coated with anti-corrosion coating and hydrophilic coating.

Because the surface is covered with a hydrophilic layer, the condensed water will quickly spread on the hydrophilic aluminum foil, and will not condense into water droplets, thus increasing the heat exchange area, speeding up the cooling and heating speed and avoiding the air flow resulting noise.

The hydrophilic performance is determined by the angle formed by the water sticking to the surface of the aluminum foil. The smaller the angle a, the better the hydrophilic performance, and vice versa, the worse the hydrophilic performance. Generally speaking, the angle of a is less than 35.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Are Popular Uses of Aluminum Foil Alloy 1235

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

-

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

-

Different Tempers of 8011 Aluminum Foil Coil

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

-

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

-

Plain or Hydrophilic Aluminum Coil for AC

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China