An Overview of Air Conditioner Aluminum Foil Tape

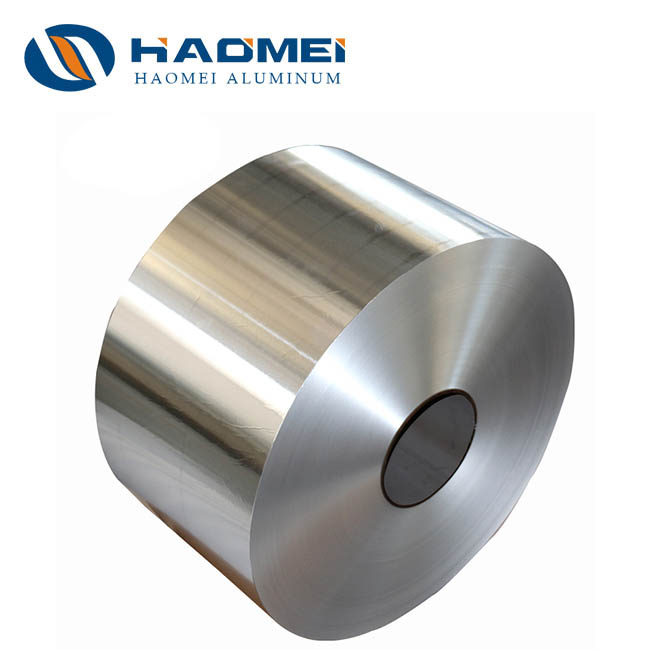

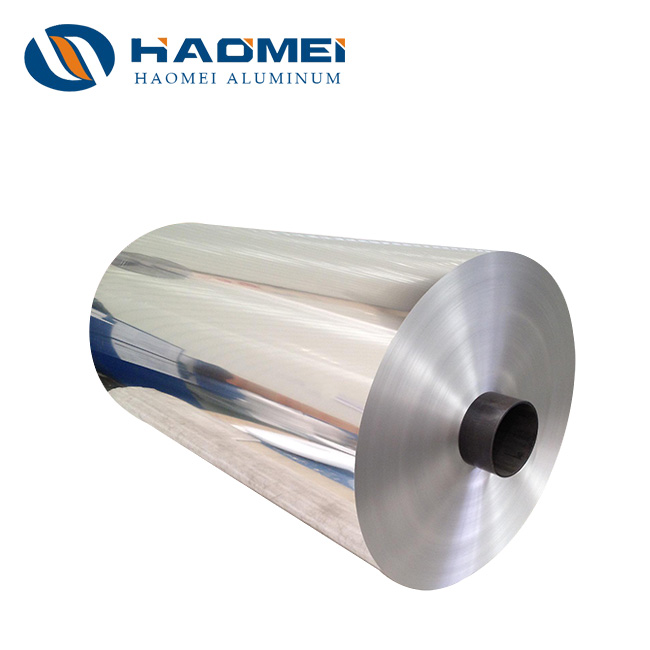

Air conditioner aluminum foil tape is mainly used in the production of heat exchanger fins. It is generally divided into aircon aluminum foil without coating and coated foil for aircon like hydrophilic aluminum foil. Learn more.

Air conditioner aluminum foil tape is mainly used in the production of heat exchanger fins, such as air-conditioning condensers and evaporators, refrigerator frost-free evaporators/finned evaporators, commercial refrigerator condensers and evaporators, automotive air-conditioning condensers and evaporators, etc. Generally, the coated one is hydrophilic aluminum foil.

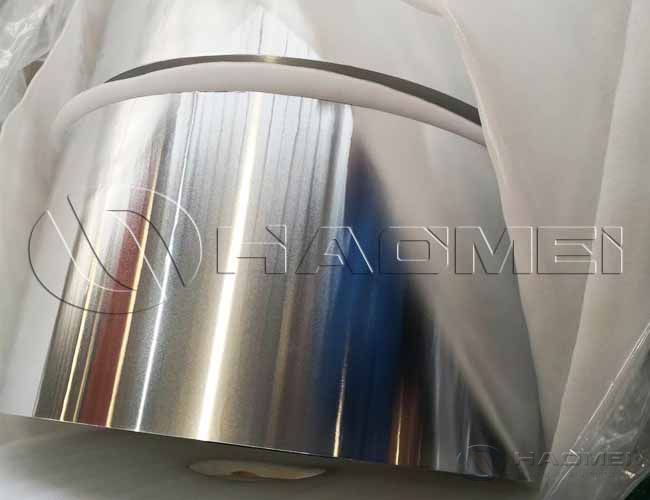

The aircon aluminum foil without any anti-corrosion coating is silver in color. At present, the fins of many air conditioners have anti-corrosion coatings, many of which are blue or green, of which the purpose is to improve the corrosion resistance of the fins.

The hydrophilic layer can make the moisture condensed on the heat exchange fins to spread out and flow down the surface, so as to avoid affecting the ventilation of the heat exchanger due to the condensation of water droplets between the heat exchange fins, thereby increasing the heat exchange rate by 5%.

The surface of the aluminum foil coated with a hydrophilic coating has a strong affinity for water, and the condensed water diffuses quickly on the fins, so the ventilation effect is good when the air conditioner is running. The index to measure hydrophilicity is called hydrophilic angle. For non-hydrophilic aluminum foil, the smaller the sheet distance, the larger the pressure drop ratio, and the lower the heat transfer efficiency of the evaporator.

For hydrophilic coated fins, the smaller the contact angle, the lower the pressure drop ratio, and the better the heat transfer efficiency of the evaporator. The hydrophilic film will age and oxidize over time, and the hydrophilic performance will obviously decline, causing condensed water to form during the cooling process and blocking the circulating air duct, which finally causes the cooling effect to decay year by year.

The production process of the coated foil for aircon requires the aluminum foil to have a good shape, which is a prerequisite for the production of coated aluminum foil. The unit to measure the plate shape is I. General coating production equipment requires a plate shape within 20-40I. If it is greater than this value, a tension straightening system needs to be added in front of the coating equipment.

Generally, the running route of coating equipment is long, and there are many processing procedures and guide rollers. Therefore, if the tension straightening system is not equipped, once the plate shape is not good, it is easy to fold during operation, resulting in failure to produce. Haomei Aluminum has mature processing technology. Welcome to leave message below to tell us which kind of air conditioner aluminum foil you need.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China