Why Is Hydrophilic Aluminum Foil Used for Air Conditioner

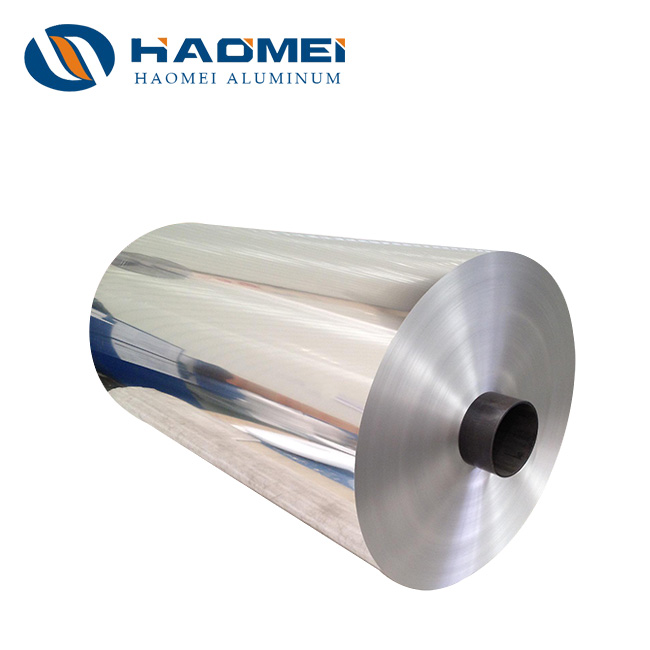

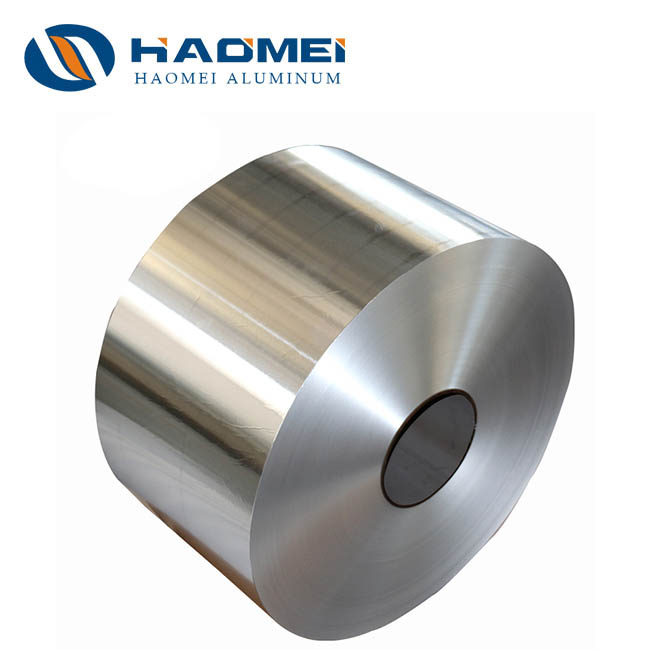

The hydrophilic aluminum foil has better heat exchange performance. Its common alloys are 1100, 1145, 3003 and 8011 aluminum ac coil. The popular colors are blue and gold aluminum foils. Learn more.

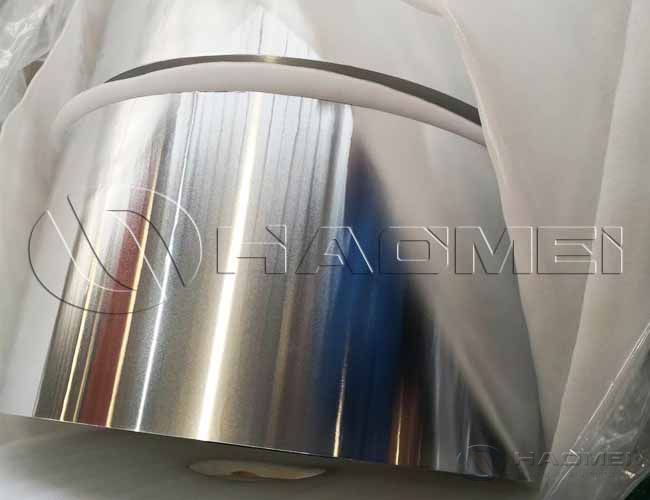

The difference between hydrophilic aluminum foil and ordinary aircon aluminum foil is that it has been surface treated - it has an additional hydrophilic layer. Since aluminum foil coated with a hydrophilic coating, its heat exchange performance is also better.

The surface of hydrophilic aluminum foil has a strong affinity for water. Condensed water spreads quickly on the fins and is not easy to form "water bridges". Therefore, its ventilation effect is good when the air conditioner is running.

The air conditioner aluminum foils are commonly used in a variety of automotive radiators, HVAC, insulation panels and air conditioning applications. 1100, 1145, 3003 and 8011 aluminum alloys are all good alloy choices due to aluminum's corrosion resistance. The colors of aircon aluminum foils are also different. Blue and gold aluminum foils are more popular.

Air conditioner aluminum foil generally chooses 3003 aluminum foil. It mainly needs to have good formability, few metallurgical defects and small anisotropy. It also requires high strength, good ductility, uniform thickness and good straightness.

The amount of aluminum foil used in air conditioners varies greatly depending on the model and power of the air conditioner. Making thinner aluminum foil can reduce the use of aluminum and reduce the cost of air conditioner radiators with the same heat exchange area.

The specific type of aluminum foil used to process heat exchange fins needs to be customized according to actual application and functional requirements. For example, whether hydrophilic or hydrophobic processes are required, and whether anti-corrosion processes are required, all need to be customized according to actual needs.

The production process of hydrophilic aluminum foil requires the aluminum ac coil to have a good shape, which is a prerequisite for the production of coated aluminum foil. The unit for measuring plate shape indicators is I. Generally, the plate shape requirements of coating production equipment are within 20-40I. If it is greater than this value, a tension straightening system needs to be added in front of the coating equipment.

Generally, the aluminum strip running route of coating equipment is long, and there are many processing steps and guide rollers. Therefore, if the tension straightening system is not equipped, once the plate shape is not good, it will easily break during operation, resulting in the failure of production.

Inquiry

Products Category

Latest Application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

-

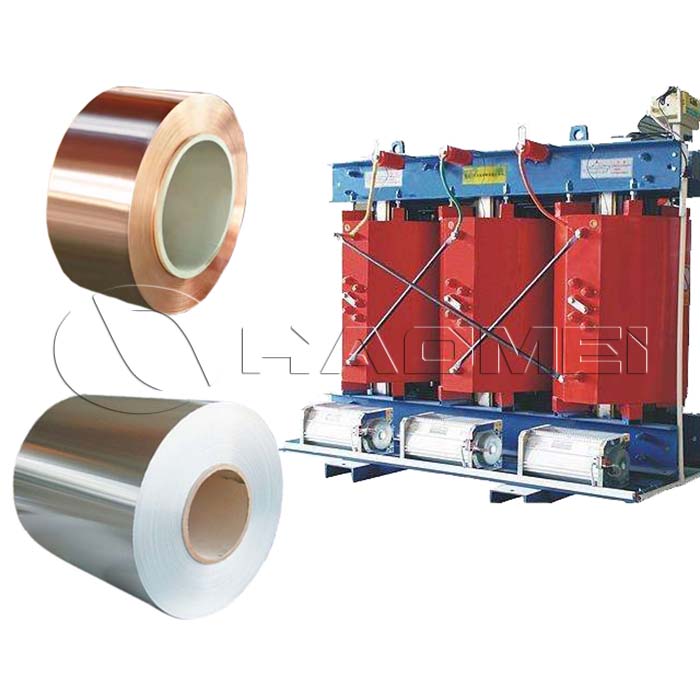

Aluminium Foil For Transformer Winding

Aluminum Foil for transformer winding is 3003, 1060, 1070 and 1050 aluminum foil. What are the advantages of pure aluminum foil for making transformer? Learn more.

application

Aluminum Foil for transformer winding is 3003, 1060, 1070 and 1050 aluminum foil. What are the advantages of pure aluminum foil for making transformer? Learn more.

application

-

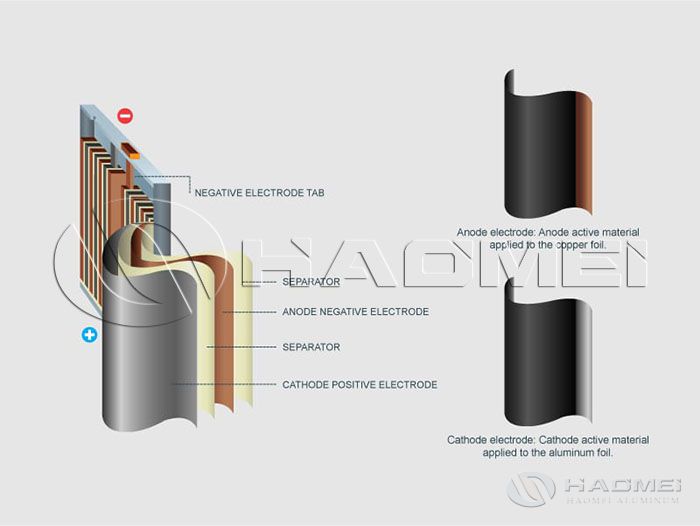

Aluminum Foil Battery for Sale

Aluminum foil battery is is used as a current collector for lithium-ion batteries. Haomei offers 1235/ 1050/1060/1070/1100 aluminum foil for you. Learn more.

application

Aluminum foil battery is is used as a current collector for lithium-ion batteries. Haomei offers 1235/ 1050/1060/1070/1100 aluminum foil for you. Learn more.

application

-

Aluminum Foil Paper for Cigarette Packaging

The aluminum foil thickness for cigarette packaging is 0.006mm to 0.007mm. The common alloys are 8011 and 8079. Learn more.

application

The aluminum foil thickness for cigarette packaging is 0.006mm to 0.007mm. The common alloys are 8011 and 8079. Learn more.

application

Latest Blog

-

In modern life, air conditioners have become an indispensable household appliance, creating a comfortable indoor environment for people. Aircon aluminum foil plays a vital role behind the efficient operation of air conditioners. Aluminum foil, with i

Blog

In modern life, air conditioners have become an indispensable household appliance, creating a comfortable indoor environment for people. Aircon aluminum foil plays a vital role behind the efficient operation of air conditioners. Aluminum foil, with i

Blog

-

Is Aluminum Foil Biodegradable

In today's era of increasing environmental awareness, we are increasingly concerned about the sustainability of the materials we use in daily life. Can aluminum foil, a material commonly used in kitchens, food packaging and industrial applications, be

Blog

In today's era of increasing environmental awareness, we are increasingly concerned about the sustainability of the materials we use in daily life. Can aluminum foil, a material commonly used in kitchens, food packaging and industrial applications, be

Blog

-

What Are 8011 Aluminium Foil Applications?

8011 aluminum foil is a metal foil made of aluminum as the main raw material through a series of rolling processes. With good formability, barrier properties and economic cost advantages, it has been widely used in packaging, air conditioning, household a

Blog

8011 aluminum foil is a metal foil made of aluminum as the main raw material through a series of rolling processes. With good formability, barrier properties and economic cost advantages, it has been widely used in packaging, air conditioning, household a

Blog

-

In the field of aluminum processing, the two pure aluminum foils 1100 and 1235 have formed differentiated application scenarios with their different composition designs and process characteristics.1. The essential difference between alloy composition and

Blog

In the field of aluminum processing, the two pure aluminum foils 1100 and 1235 have formed differentiated application scenarios with their different composition designs and process characteristics.1. The essential difference between alloy composition and

Blog

-

What Is Heavy Duty Aluminum Foil Thickness

In the family of material science, aluminum foil stands out for its unique properties and is widely used in many fields. Aluminum foil can be divided into light, standard and heavy according to thickness.Thickness definition of heavy aluminum foilGen

Blog

In the family of material science, aluminum foil stands out for its unique properties and is widely used in many fields. Aluminum foil can be divided into light, standard and heavy according to thickness.Thickness definition of heavy aluminum foilGen

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China