Aluminum Foil for Food Packaging

The aluminum foil has been an important packaging for food for a long time, including 1060, 1100, 3003, 8021 and 8011 aluminum foil jumbo roll. What are its advantages? Learn more.

Aluminum foil was first produced in France in 1903. In 1911, a brand based in Bern, Switzerland, began wrapping its chocolate bars in aluminum foil. Their unique triangular packaging is still widely available today. At that time, aluminum foil, as the most expensive packaging material, was only used for high-end packaging. It gradually became popular instead of tin foil.

After nearly a century of development, aluminum foil has become a major packaging material, and its market development is mature in many countries. Aluminum foil for food packaging has greatly improved the mechanization and automation level of food processing, and accelerated the modernization and socialization of people's diet and life.

In the aluminum foil consumer market, aluminum foil for packaging is the most important application field. After compounding it with other materials, it can be used for food packaging, pharmaceutical packaging, tobacco packaging, beer labeling, and daily chemical packaging. Among them, aluminum foil for tobacco packaging accounts for 36% of the total, food packaging accounts for 27%, and pharmaceutical packaging accounts for 22%.

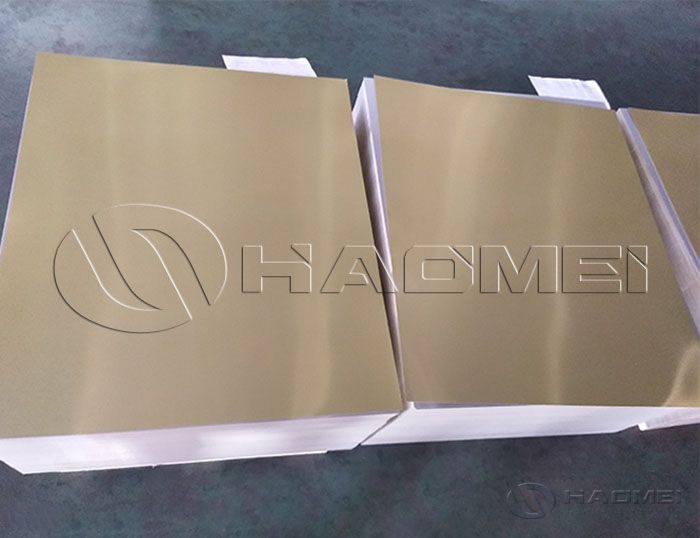

There are 1 series, 3 series and 8 series of aluminum foil for food packaging. The alloyss include 1060, 1100, 3003, 8011, 8021 aluminum foil, etc. The common tempers are H14, H16 and H18. They can be used for packaging cooked food, meat products, seafood, braised products, fried products, soy products, etc.

The aluminum foil for pharmaceutical packaging is mainly 8011 aluminum foil, 8021 aluminum foil, and 8079 aluminum foil. The tempers are O, H14, H16, H18,etc. The product thickness range is 0.016-0.2mm. At present, it is widely used in ptp capsule medicine board, blister packaging, tropical blister packaging, medical bottle caps and other fields.

Advantages of aluminum foil food packaging

1. Compared with plastic packaging, it will not release toxic substances under high temperature, which is safe and hygienic.

2. Compared with paper packaging, 8011 aluminum foil jumbo roll has high temperature resistance, good thermal insulation, and oil resistance.

3. Compared with glass packaging, aluminum foil packaging has high mechanical strength, is not fragile, and is easy to transport and store.

4. Aluminum foil packaging has the advantages of easy recycling, green environmental protection, good shading performance, water resistance,etc.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

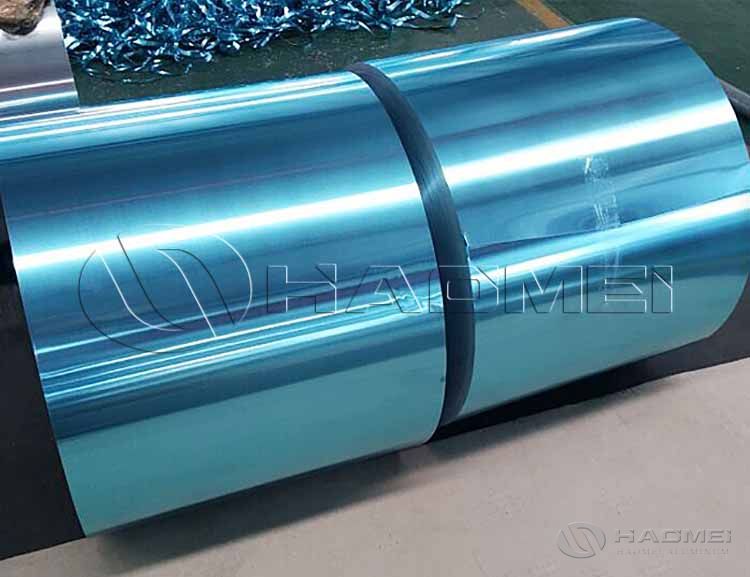

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Are Popular Uses of Aluminum Foil Alloy 1235

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

-

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

-

Different Tempers of 8011 Aluminum Foil Coil

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

-

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

-

Plain or Hydrophilic Aluminum Coil for AC

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China