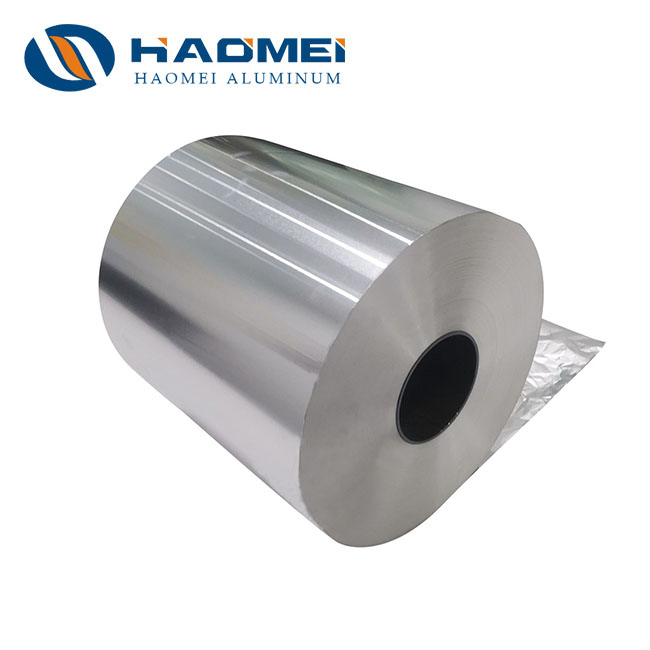

Aluminum Foil for HDPE Bottle Sealing

The aluminum foil is often used as the hdpe bottle sealing. One of the alloys is aluminum foil 8011. What are its advantages as the HDPE bottle sealing? Welcome to learn more.

HDPE bottles refer to medicinal plastic bottles produced by blow molding and injection molding with HDPE (high density polyethylene) as the main raw material. Its characteristics are non-toxic and odorless. Its hardness, tensile strength and creep are better than low density polyethylene. It has good wear resistance, electrical insulation, toughness and cold resistance.

HDPE bottles are mostly used for the packaging of oral solid medicines, capsules, tablets and other medicines. The mouth of the hollow container is sealed with an aluminum foil electromagnetic induction gasket, which increases the safety protection of the medicines. Aluminum foil for HDPE bottle sealing has many advantages. The heat-sealing aluminum foil is safer and healthier for medicines. The surface of the aluminum foil is very clean, and any bacteria or microorganisms cannot grow and reproduce on the surface of the aluminum foil. It will not produce peculiar smell. The aluminum foil is resistant to corrosion, oxidation, and acid hydrolysis, having long shelf life.

The compatibility of aluminum foil with heat-sealing varnishes, combined with the metal's excellent thermal conductivity and stability, make it an ideal material for capping and heat-sealing various HDPE bottles.

Only the metal foil is heated by the high frequency electromagnetic field applied after filling and capping. While the seal is reliable, the foil peels cleanly due to the coating's combination of seal strength and peelability.

Aluminum foil 8011 is often compounded with materials with good heat sealing performance or high barrier properties such as PP, HDPE, PET, BOPA, CPP, etc. Aluminum foil is to increase the barrier performance and shading.

8011 aluminum foil is a commonly used packaging aluminum foil, which has the characteristics of heat preservation, moisturizing, fresh-keeping, light-proof and anti-penetration. It is used as a food and medicine packaging material and has good stability and packaging effect.

Haomei Aluminum has strict control of raw material and mature production process. Due to the strict limitation of rolling oil components, the residual amount of rolling oil on the surface of the aluminum foil is greatly reduced, so that the heat sealing strength is increased from 7-10 MPa in the past to 20-24 MPa. Welcome to leave message below to inquire aluminum sealing foil.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

What Are Popular Uses of Aluminum Foil Alloy 1235

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

1235 aluminum foil, with its high purity (typically aluminum content exceeding 99.35%), excellent ductility, superior processing properties, and manageable costs, has defied the traditional perception that aluminum foil is "only used for packaging.&q

Blog

-

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

In fields such as packaging, electronics, and pharmaceuticals, 1050 pure aluminum foil, with its high purity of ≥99.5%, combines corrosion resistance, ease of processing, and lightweight advantages, making it a fundamental material in numerous industries.

Blog

-

Different Tempers of 8011 Aluminum Foil Coil

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

The manganese content of 8011 aluminum foil coil typically ranges from 0.8% to 1.2%. This compositional design avoids the inherent strength limitations of pure aluminum (1 series) while also being less difficult to process than higher-hardness alloys

Blog

-

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

Aluminum foil jumbo roll, while seemingly insignificant, is a critical material for ensuring heat dissipation efficiency, durability, and overall performance in air conditioner outdoor units. This is especially true in the core components of the outd

Blog

-

Plain or Hydrophilic Aluminum Coil for AC

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Aluminum foil is a core component in air conditioner heat exchangers, and its performance directly impacts the cooling and heating efficiency, energy consumption, and service life of the air conditioner. Currently, plain aluminum foil jumbo roll and hydro

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China