Aluminum Foil Large Rolls for Cable

The surface quality of aluminum foil is the most important factor affecting the peel strength of the cable foil. What are the main problems of aluminum foil large roll and how to avoid it? Learn more.

The exterior of the communication cable needs to be wrapped with a layer of aluminum foil for protection and shielding. This kind of aluminum foil large rolls are usually made of 1145 grade industrial pure aluminum. After continuous casting and rolling, cold rolling, slitting and complete annealing, it is divided into small rolls according to the length required by the user and supplied to the cable foil compounding factory.

Cable aluminum foil is made by attaching a special plastic film (0.058mm thick) on the upper and lower surfaces of the 0.15-0.20mm thick aluminum foil. The surface quality of aluminum foil is the most important factor affecting the peel strength, and its main surface quality problems are oil spots, corrosion, peroxidation, etc.

1. Oil spot

Oil spots are the most common quality problems on the surface of aluminum foil. The main reason is that the rolling oil is mixed with machine oil or the rolling oil has a high kinematic viscosity. In addition, the angle of the air nozzle at the exit of the rolling mill is incorrect, or the air pressure is too small.

The solution is: a. prevent the oil from mixing into the rolling oil; b. control the kinematic viscosity of the rolling oil, and it should not exceed 2.34×10 m2/s; c. heat the rolling oil in cold weather; d. control the amount of additives within 5 % to 7%; e. Add two rows of air nozzles at the exit of the rolling mill, 2 nozzles in the upper row and 4 nozzles in the lower row, blowing from the middle to both sides; d. Manually wipe off the oil on the surface of the aluminum foil in the last rolling pass; f. When the aluminum foil is annealed, stay at 200°C for a period of time to allow the rolling oil to fully evaporate.

2. Corrosion

Many people confuse the corrosion and oxidation of aluminum foil. In fact, the two are completely different. Corrosion is the loss of electrons by aluminum atoms to form white powder, and the product has no protective effect on the substrate; oxidation is the synthesis of oxides by aluminum atoms and oxidation, and the product has a protective effect on the aluminum substrate. Aluminum will form a layer of oxide film about 1/500 micron in nature to protect itself. After the aluminum foil is corroded, the white ash formed on the surface will seriously reduce the peel strength of the plastic-coated foil. The corrosion of the aluminum foil is caused by water or lye.

Aluminum foil being wet by rain during transportation is a common cause of corrosion. Another neglected is caused by fog. When the aluminum foil jumbo roll s transported for a long distance at night at high temperature, one side of the aluminum coil is cooled quickly, and the other side is at high temperature.

The mist in the cooling place condenses on it and penetrates into the aluminum coil. After it is transported to the customer's warehouse, the high temperature side heats the low temperature side, causing the aluminum coil to corrode.

The solution is that the 1000 ft roll aluminum foil should be tightly packaged to prevent rain and aluminum coils in high temperature state should not be packaged and transported.

3. Peroxidation

A layer of oxide film naturally formed on the surface of aluminum has a protective effect, but if it is cooled by strong wind at high temperature, it will inevitably cause peroxidation and surface discoloration.

Overoxidized aluminum foil also reduces the peel strength of the cable foil. The prevention method is that after the aluminum foil is annealed out of the furnace, it cannot be cooled by strong wind, and it is allowed to cool slowly. If you need aluminum foil roll for cable foil compounding, welcome to contact us directly.

Inquiry

Products Category

Latest Application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

-

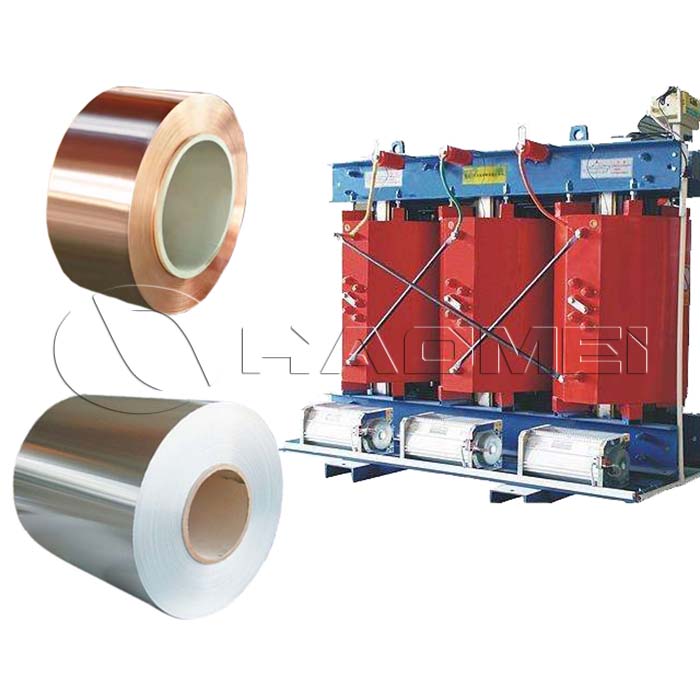

Aluminium Foil For Transformer Winding

Aluminum Foil for transformer winding is 3003, 1060, 1070 and 1050 aluminum foil. What are the advantages of pure aluminum foil for making transformer? Learn more.

application

Aluminum Foil for transformer winding is 3003, 1060, 1070 and 1050 aluminum foil. What are the advantages of pure aluminum foil for making transformer? Learn more.

application

-

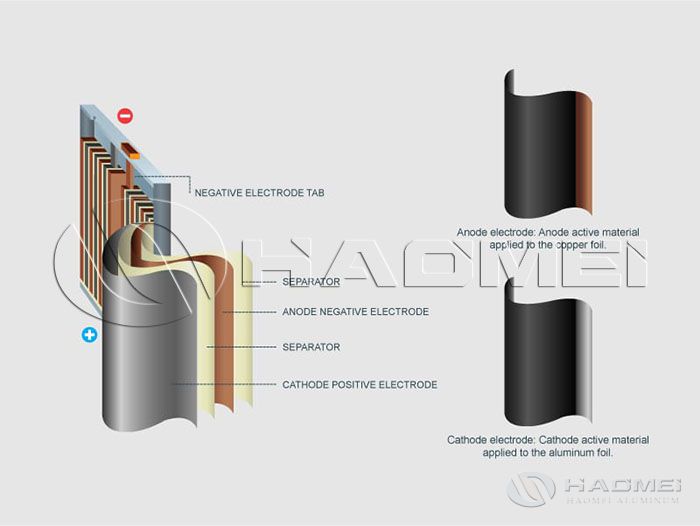

Aluminum Foil Battery for Sale

Aluminum foil battery is is used as a current collector for lithium-ion batteries. Haomei offers 1235/ 1050/1060/1070/1100 aluminum foil for you. Learn more.

application

Aluminum foil battery is is used as a current collector for lithium-ion batteries. Haomei offers 1235/ 1050/1060/1070/1100 aluminum foil for you. Learn more.

application

-

Aluminum Foil Paper for Cigarette Packaging

The aluminum foil thickness for cigarette packaging is 0.006mm to 0.007mm. The common alloys are 8011 and 8079. Learn more.

application

The aluminum foil thickness for cigarette packaging is 0.006mm to 0.007mm. The common alloys are 8011 and 8079. Learn more.

application

Latest Blog

-

In modern life, air conditioners have become an indispensable household appliance, creating a comfortable indoor environment for people. Aircon aluminum foil plays a vital role behind the efficient operation of air conditioners. Aluminum foil, with i

Blog

In modern life, air conditioners have become an indispensable household appliance, creating a comfortable indoor environment for people. Aircon aluminum foil plays a vital role behind the efficient operation of air conditioners. Aluminum foil, with i

Blog

-

Is Aluminum Foil Biodegradable

In today's era of increasing environmental awareness, we are increasingly concerned about the sustainability of the materials we use in daily life. Can aluminum foil, a material commonly used in kitchens, food packaging and industrial applications, be

Blog

In today's era of increasing environmental awareness, we are increasingly concerned about the sustainability of the materials we use in daily life. Can aluminum foil, a material commonly used in kitchens, food packaging and industrial applications, be

Blog

-

What Are 8011 Aluminium Foil Applications?

8011 aluminum foil is a metal foil made of aluminum as the main raw material through a series of rolling processes. With good formability, barrier properties and economic cost advantages, it has been widely used in packaging, air conditioning, household a

Blog

8011 aluminum foil is a metal foil made of aluminum as the main raw material through a series of rolling processes. With good formability, barrier properties and economic cost advantages, it has been widely used in packaging, air conditioning, household a

Blog

-

In the field of aluminum processing, the two pure aluminum foils 1100 and 1235 have formed differentiated application scenarios with their different composition designs and process characteristics.1. The essential difference between alloy composition and

Blog

In the field of aluminum processing, the two pure aluminum foils 1100 and 1235 have formed differentiated application scenarios with their different composition designs and process characteristics.1. The essential difference between alloy composition and

Blog

-

What Is Heavy Duty Aluminum Foil Thickness

In the family of material science, aluminum foil stands out for its unique properties and is widely used in many fields. Aluminum foil can be divided into light, standard and heavy according to thickness.Thickness definition of heavy aluminum foilGen

Blog

In the family of material science, aluminum foil stands out for its unique properties and is widely used in many fields. Aluminum foil can be divided into light, standard and heavy according to thickness.Thickness definition of heavy aluminum foilGen

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China