How to Control Aluminum Foil Quality

1235 and 8011 aluminum foil are two popular choices with wide applications. How to control their quality? It should start from the melt quality. The melt quality can generally be measured by two indicators. Learn more.

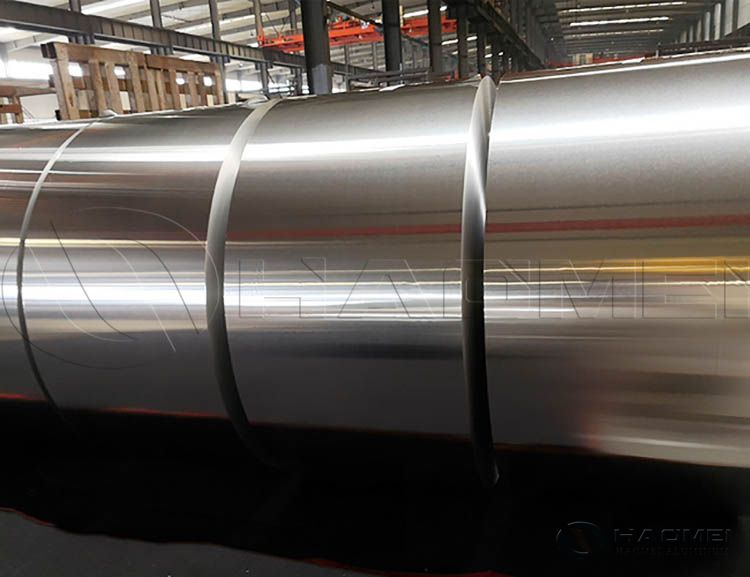

1235 and 8011 aluminum foil roll are two popular choices with wide applications in battery, bottle sealing, food packaging, hair beauty, food container and pharmaceutical packaging. How to control their quality? It should start from the melt quality.

The melt quality can generally be measured by two indicators: the inclusion content in the solid structure and the hydrogen content in the liquid melt. When smelting aluminum and aluminum alloys, it is inevitable that the melt is polluted by hydrogen and inclusions. Their content in the aluminum melt is an important indicator to measure the quality of the melt.

Aluminum and its alloys show the characteristics of easy oxidation and gas absorption during the smelting process, which makes it easy to form gases and inclusions in the molten aluminum, resulting in a series of defects such as air channels, pinholes, and inclusions in the final product, resulting in the break of processing during rolling.

The non-metallic inclusions in molten aluminum are mainly metal oxide inclusions, part of which comes from the furnace charge, and most of them are formed by the reaction of aluminum and oxygen during the melting and casting process, among which the melting temperature, melting conditions, slag content in the furnace, the quality of the charge, the way of the converter, and the masonry conditions of the furnace all have an impact on the amount of inclusions in the melt. Aluminum reacts with O2, N2, CO2, CO, etc. in the furnace gas to form alumina impurities.

Charges include aluminum ingots, master alloys, additives, and scrap at various levels. Among them, the alumina content in the aluminum ingot fluctuates in the range of 0.2×10-4%~2×10-4%. Others such as slag and waste have a large amount of oxidized inclusions, especially waste contaminated by oil and soil, which greatly increases the content of hydrogen and inclusions in the melt. Therefore, the purity of the charge itself is low, and the composition of the charge must be strictly controlled to produce high-quality 1235 aluminum foil.

The aluminum ingots put into production must be stored in a dry and clean environment, and it is strictly forbidden to join the production of wet ingots. The proportion of waste should be strictly controlled and must be less than 20%. Oily waste, tertiary waste and sorted out aluminum-containing slag cannot be added to the furnace for producing 1235 aluminum foil blanks. The order of feeding should be in accordance with the order in which the waste is added first and then the aluminum ingots are added to prevent the burning of the waste from causing oxidation inclusions.

In actual production, regular heat cleaning must be carried out, and the heat cleaning of the smelting furnace and holding furnace must be maintained at least once a week. Use specific tools to clean the slag on the surface of the furnace group and remove it from the furnace body. Moreover, the furnace group must be thoroughly cooled once a year to completely remove the slag accumulation in the furnace group and create a good environment for smelting production.

Inquiry

Products Category

Latest Application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

-

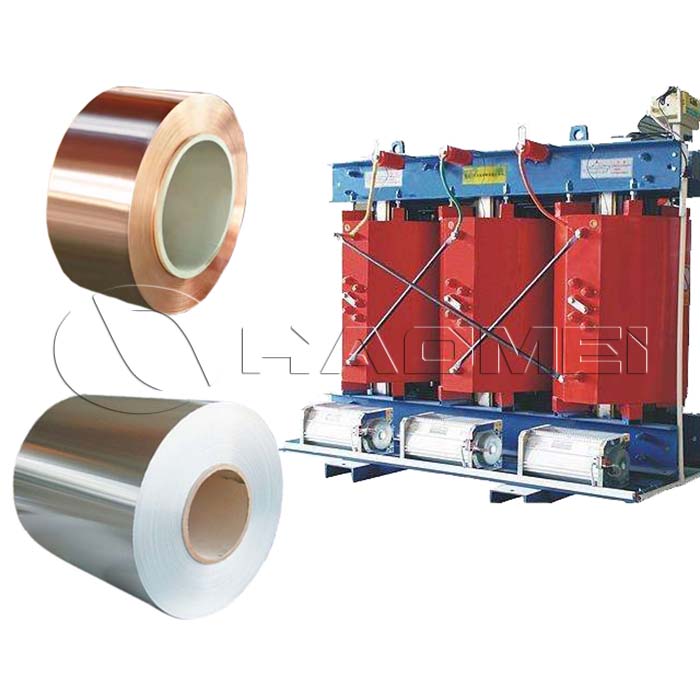

Aluminium Foil For Transformer Winding

Aluminum Foil for transformer winding is 3003, 1060, 1070 and 1050 aluminum foil. What are the advantages of pure aluminum foil for making transformer? Learn more.

application

Aluminum Foil for transformer winding is 3003, 1060, 1070 and 1050 aluminum foil. What are the advantages of pure aluminum foil for making transformer? Learn more.

application

-

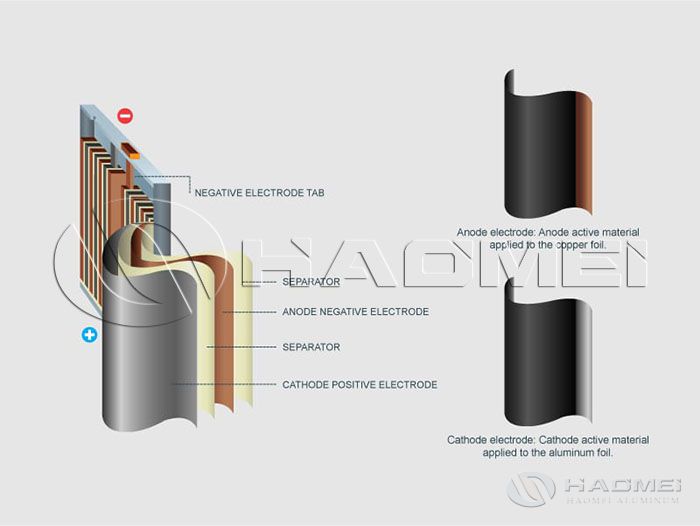

Aluminum Foil Battery for Sale

Aluminum foil battery is is used as a current collector for lithium-ion batteries. Haomei offers 1235/ 1050/1060/1070/1100 aluminum foil for you. Learn more.

application

Aluminum foil battery is is used as a current collector for lithium-ion batteries. Haomei offers 1235/ 1050/1060/1070/1100 aluminum foil for you. Learn more.

application

-

Aluminum Foil Paper for Cigarette Packaging

The aluminum foil thickness for cigarette packaging is 0.006mm to 0.007mm. The common alloys are 8011 and 8079. Learn more.

application

The aluminum foil thickness for cigarette packaging is 0.006mm to 0.007mm. The common alloys are 8011 and 8079. Learn more.

application

Latest Blog

-

In modern life, air conditioners have become an indispensable household appliance, creating a comfortable indoor environment for people. Aircon aluminum foil plays a vital role behind the efficient operation of air conditioners. Aluminum foil, with i

Blog

In modern life, air conditioners have become an indispensable household appliance, creating a comfortable indoor environment for people. Aircon aluminum foil plays a vital role behind the efficient operation of air conditioners. Aluminum foil, with i

Blog

-

Is Aluminum Foil Biodegradable

In today's era of increasing environmental awareness, we are increasingly concerned about the sustainability of the materials we use in daily life. Can aluminum foil, a material commonly used in kitchens, food packaging and industrial applications, be

Blog

In today's era of increasing environmental awareness, we are increasingly concerned about the sustainability of the materials we use in daily life. Can aluminum foil, a material commonly used in kitchens, food packaging and industrial applications, be

Blog

-

What Are 8011 Aluminium Foil Applications?

8011 aluminum foil is a metal foil made of aluminum as the main raw material through a series of rolling processes. With good formability, barrier properties and economic cost advantages, it has been widely used in packaging, air conditioning, household a

Blog

8011 aluminum foil is a metal foil made of aluminum as the main raw material through a series of rolling processes. With good formability, barrier properties and economic cost advantages, it has been widely used in packaging, air conditioning, household a

Blog

-

In the field of aluminum processing, the two pure aluminum foils 1100 and 1235 have formed differentiated application scenarios with their different composition designs and process characteristics.1. The essential difference between alloy composition and

Blog

In the field of aluminum processing, the two pure aluminum foils 1100 and 1235 have formed differentiated application scenarios with their different composition designs and process characteristics.1. The essential difference between alloy composition and

Blog

-

What Is Heavy Duty Aluminum Foil Thickness

In the family of material science, aluminum foil stands out for its unique properties and is widely used in many fields. Aluminum foil can be divided into light, standard and heavy according to thickness.Thickness definition of heavy aluminum foilGen

Blog

In the family of material science, aluminum foil stands out for its unique properties and is widely used in many fields. Aluminum foil can be divided into light, standard and heavy according to thickness.Thickness definition of heavy aluminum foilGen

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China