Is Aluminum Foil for Transformer Winding Good

Aluminum foil winding are the main choice for different transformers such as dry and low voltage in North America. 1070 aluminum foil roll is a popular choice.What should be payed attention to? Learn more.

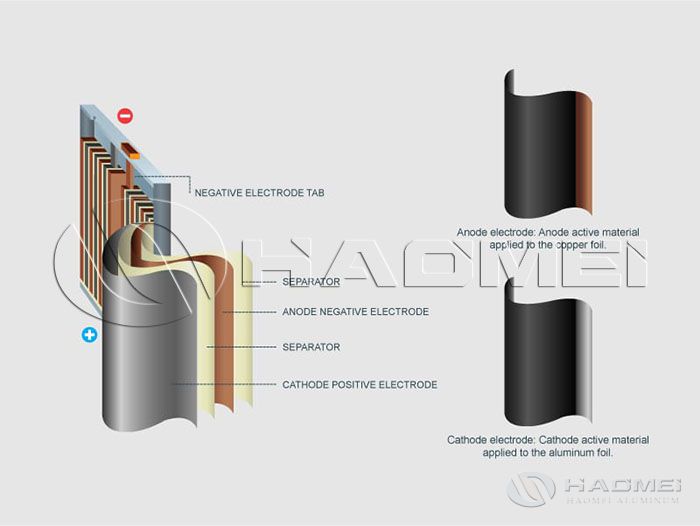

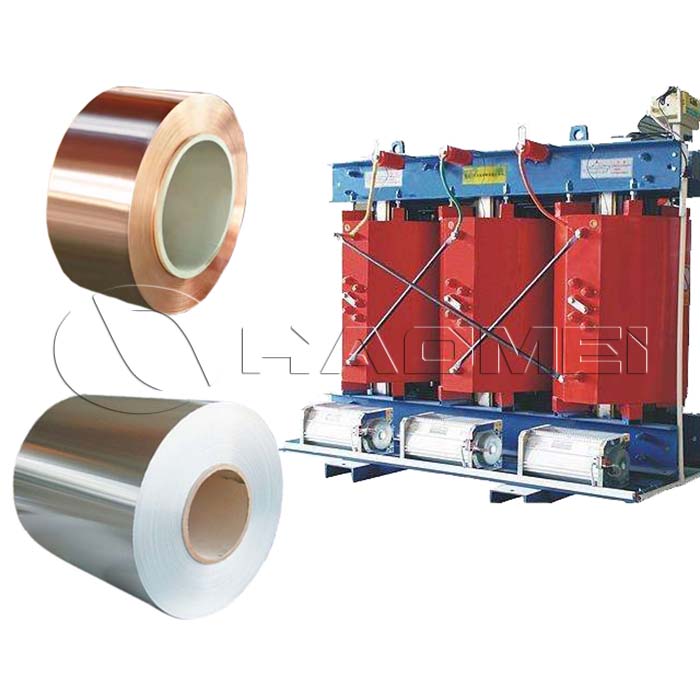

At present, dry-type transformers generally choose low-voltage foil winding and high-voltage wire winding. Aluminum foil winding is the main choice for different transformers such as dry and low voltage in North America. Aluminum's maximum resistivity provides fewer eddy current losses within the winding, which reduces the likelihood of hot spots. Transformers with aluminum or copper winding have the same losses and performance.

Aluminum foil jumbo roll for transformers range from 0.2mm to 3.5mm in thickness and 10mm to 1600mm in width. The coils are wound on insulating materials such as paper, kraft paper, mylar or glass cloth. Aluminum foil has high electrical conductivity, good corrosion resistance and aesthetic appearance. Aluminum foil for transformer winding is an essential material in the production of transformers.

When foil winding, the aluminum foil must be tensioned to maintain a certain tension, and wound into a winding coil smoothly and flatly. The thicker the aluminum foil, the greater the tension required. The maximum tension of the foil winding machine is limited, exceeding the maximum tension of the machine is dangerous.

If the tension is too small, the wound coil is too loose, and the size requirements cannot be guaranteed. Therefore, this is not to say that you need to increase the thickness of the aluminum foil, because the transformer designer can comprehensively consider the thickness, cross-section, current density, temperature rise, etc. of the aluminum foil, instead of blindly adjusting the thickness to design and calculate the winding characteristics of the transformer.

The aluminum alloys for transformer winding are usually 1060, 1050, 1050A, 1060, 1070, 1070A and 1350. The temper is O. O represents the soft state, and numbers can be used to indicate the degree of softness and hardness, and the degree of annealing. The thickness is between 0.08-3.00 mm.

Alloys | 1050, 1350, 1060, 1070 |

Temper | O |

Thickness | 0.2-3.5 mm |

Width | 10-1600 mm |

Conductivity | 1050 O aluminum foil: over 60% ACS 1060 O aluminum foil: over 61.5% ACS 1070 O aluminum foil: over 62.7% ACS 1350 O aluminum foil: over 62% ACS |

1070 aluminum foil roll is an alloy with the highest purity in the pure aluminum series. It has the characteristics of high plasticity, low strength, excellent corrosion resistance, good electrical conductivity and thermal conductivity, and its electrical conductivity can reach more than 35.7 S/m. It is mainly used in transformer accessories.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China