The Market Prospect of Electronic Foil

The growth rate of the aluminum electrolytic capacitor industry determines the demand space of the electronic aluminum foil industry chain. The electronic foil also has many types. Learn more.

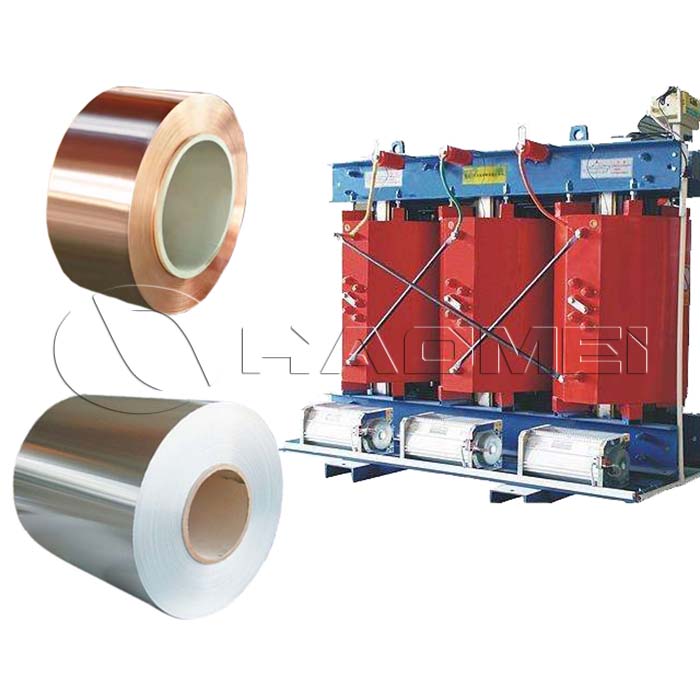

The entire industrial chain of electronic foil covers upstream resources and smelting (production of high-purity aluminum); midstream electrode foil manufacturing (electronic aluminum foil manufacturing, corrosion, chemical formation); downstream electronic component manufacturing and consumption (aluminum electrolytic capacitors, electronic complete machines).

About 70% of high-purity aluminum enters the electronic aluminum foil industry chain, and electrode foil accounts for 30-60% of the cost of aluminum electrolytic capacitors. The growth rate of the aluminum electrolytic capacitor industry determines the demand space of the electronic aluminum foil industry chain.

Electronic aluminum foil connects the two industries of aluminum processing and capacitor manufacturing. Its production needs to go through two stages of aluminum foil rolling and corrosion formation. The main process is relatively independent. The back-end corrosion and formation process will affect the quality of the final aluminum foil and the performance of the terminal capacitor.

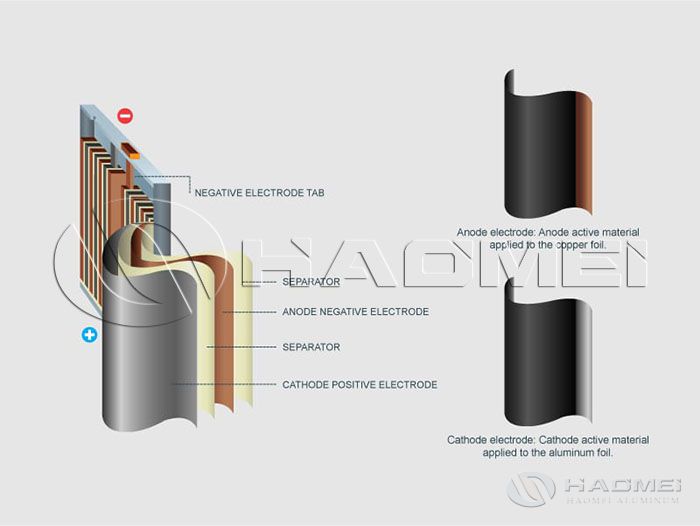

Electronic aluminum foil(plain aluminum foil like 1050 aluminum foil roll) is obtained from high-purity aluminum ingots through special refining, calendering, cleaning and cutting processes, and then processed by erosion process to obtain corroded foil, and corroded foil is anodized to obtain formed foil.

The corrosion process pits the plain aluminum foil, increasing its surface area and thus giving aluminum electrolytic capacitors high capacitance. Electrode foil is one of the most technical parts in the industrial chain of aluminum electrolytic capacitors.

Electrode foil is a special material for aluminum electrolytic capacitors. About 95% of electrode foils are used in the production of aluminum electrolytic capacitors, and its industrial development is highly dependent on aluminum electrolytic capacitors.

The performance of the electrode foil determines many key technical indicators such as the capacity, leakage current, loss, life, and reliability of the aluminum electrolytic capacitor to a certain extent.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Price Comparison Of Different Types Of Aluminum Foils

Aluminum foil jumbo roll is a versatile metallic material used in life, industry and medicine. Learn about the price ranges of household, air conditioning and pharmaceutical-grade aluminum foil, and the key factors causing their price differences.

Blog

Aluminum foil jumbo roll is a versatile metallic material used in life, industry and medicine. Learn about the price ranges of household, air conditioning and pharmaceutical-grade aluminum foil, and the key factors causing their price differences.

Blog

-

Aluminum Foil Specification for Food Container

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

-

2026 China Aluminum Foil Export Price Forecast

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China