Pharmaceutical Foil for Blister Packaging

Pharmaceutical foil including 8011, 8021 and 8079 alloy has become an important component of medicine packaging. How to test whether these medicine aluminum foil is qualified? Learn more.

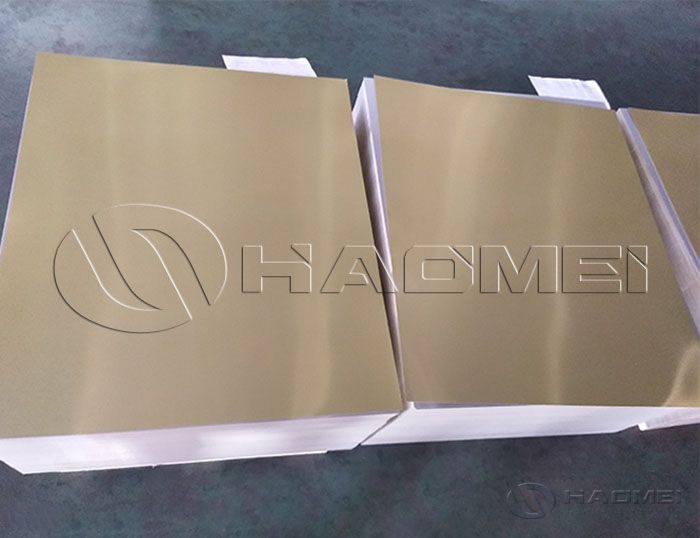

Pharmaceutical foil has become an important component of medicine packaging. The aluminum foil packaging can control the dose. Whether it is taken by itself or according to the doctor's order, the aluminum-plastic blister packaging can provide an accurate dose. The pharmaceutical packaging aluminum foils are usually 8011, 8021, 8079,etc.

High-sealing tropical packaging aluminum is a packaging material with high sealing, moisture-proof, anti-drug volatilization and anti-ultraviolet radiation used in high-grade drugs such as anti-inflammatory drugs.

Tropical medicinal aluminum foil is also called aluminum plastic aluminum, which is equivalent to adding a layer of cold stamping aluminum foil cover on the outside of thermoformed plastic blister and PTP aluminum foil. 8021-O and 8079-O are often used.

In addition to the function of barrier properties, the intermediate aluminum foil layer used in cold stamping also has functions such as strength support and resistance to stamping and stretching, so it is different from the general aluminum foil for flexible packaging.

The aluminum foil used in cold stamping is with extremely high strength and good extensibility. Since the cold stamped hard sheet needs to be stamped and formed, the thickness of the aluminum foil used is also much thicker than that of the ordinary composite film, generally 45μm.

Aluminum foil, especially thin aluminum foil, inevitably has various defects, and pinholes are the most important one. The size and number of pinholes are one of the important metrics to measure the quality level of aluminum foil.

The surface of the aluminum foil is allowed to have pinholes visible to the naked eye, but the pinholes shall not be densely arranged, and the diameter of the pinholes of the medicinal aluminum foil shall not be greater than 0.3 mm, and shall not exceed 5/m2.

During use of blister foil packaging, if its inherent quality is poor, foil breakage and rupture will often occur in production, thus affecting the printing and coating. The testing instrument is a burst strength tester. The method is to take three pieces of 40mm x 40mm samples from the finished product, put them in the gap of the instrument one by one, turn on the oil pump, and measure the indicated value on the pressure gauge. The burst strength should be greater than 98Kpa.

The standard thickness of medicine aluminum foil is 0.02 ± 0.002 mm. The thickness detection is often to check the thickness and width of the aluminum foil before putting it on the machine. Thickness detection is measured with a microcard or LG-l optical thickness meter with an accuracy of 0.5-1.0 um.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

-

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

Food tray aluminum foil for baking and ready meals: compare alloys, tempers, gauges, coatings, and QA points to reduce leaks and improve formability.

Blog

-

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

Food container aluminum foil explained: grades, temp limits, coatings, sealing, and QC checks for bulk supply of aluminum foil containers.

Blog

-

Industrial Aluminum Foil Thickness Selection Guide

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

The choice of thickness for industrial aluminum foil directly determines its mechanical properties, functional adaptability, and usage cost,etc. How to choose proper thickness? Learn more.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China