The Manufacturing Methods of Aluminum Foil for Bottle Cap

Aluminum foil for bottle cap is of rich alloys like 1060, 8011, 3105, 8079,etc. What are its manufacturing methods?

Aluminium foil for bottle cap is of rich alloys like 1060, 8011, 3105, 8079,etc. What are its manufacturing methods?

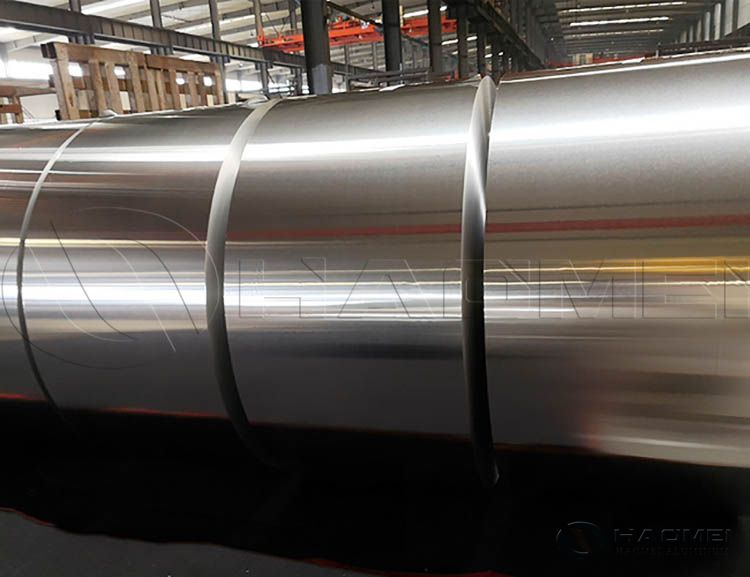

The aluminum foil blank is a cold-rolled aluminum coil with a thickness of 0.4-0.7mm and has a high multiple deformation rate. The aluminum foil blank is first pre-quenched at 240-480 ° C, and then sent to a roller with high hardness and high finish.

After rough rolling, intermediate rolling and finishing rolling, it is rolled into aluminum sheet and finally aluminum foil is formed after quenching. The aluminum foil thickness can be controlled by adjusting the tension, the rolling force of rough rolling, and the speed of finishing rolling.=

During finish rolling, the thickness of the foil decreases as the rolling speed increases; the greater the tension, the smaller the thickness. The minimum thickness produced by the belt production method can reach 0.0025mm, and the width can reach 1800mm. This kind of unprocessed aluminum foil is called plain foil. Generally, according to different uses, the plain aluminum foil should be further processed to make more advanced packaging materials.

Deep processing mainly includes:

Lamination

The aluminum foil is laminated with plastic film, paper, cellophane, etc. with an adhesive or coated with PE, etc. to form a composite film for various purposes.

Coating

Aluminum foil can be painted in various colors to improve its decorative performance.

Color printing

Aluminum foil can be directly printed or printed after surface coating, generally using flexographic printing, gravure printing and screen printing. The printed aluminum foil is a popular packaging material for bottle cap. Its special luster is matched with the ink, which has a good decorative effect on commodities.

Embossing

Aluminum foil can be used to emboss variouspatterns on the embossing machine, which is used for wrapping food and has a very decorative effect. Aluminum foil embossing can also improve its surface flatness and eliminate its slight wrinkles.

Haomei Aluminum has rich kinds of aluminum foils like 1060 aluminum foil and 8011 aluminum foil. Welcome to leave message below to inquire what you need.

Inquiry

Products Category

Latest Application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

-

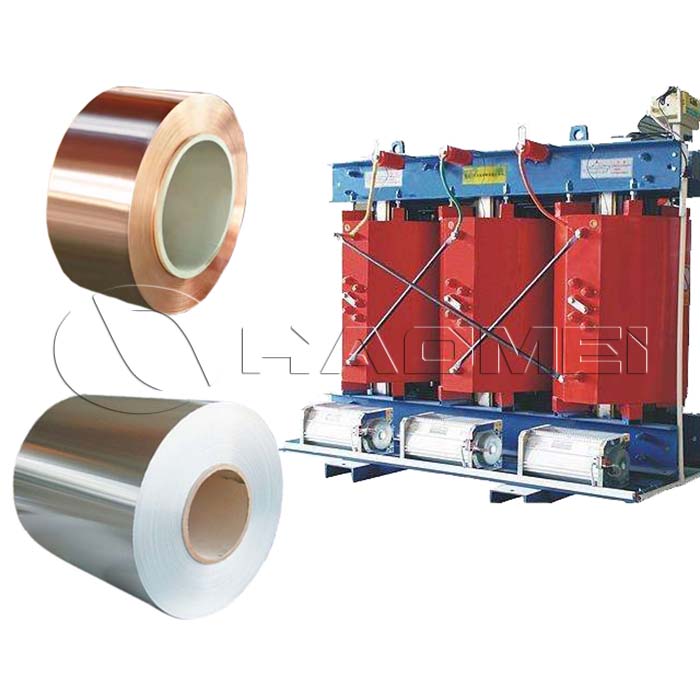

Aluminium Foil For Transformer Winding

Aluminum Foil for transformer winding is 3003, 1060, 1070 and 1050 aluminum foil. What are the advantages of pure aluminum foil for making transformer? Learn more.

application

Aluminum Foil for transformer winding is 3003, 1060, 1070 and 1050 aluminum foil. What are the advantages of pure aluminum foil for making transformer? Learn more.

application

-

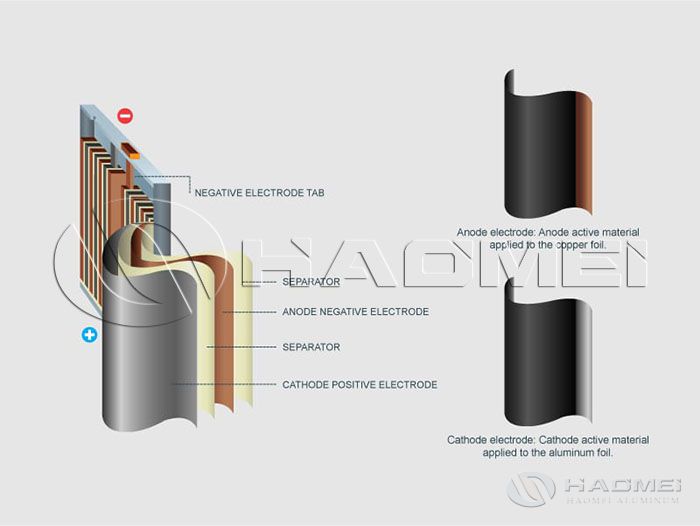

Aluminum Foil Battery for Sale

Aluminum foil battery is is used as a current collector for lithium-ion batteries. Haomei offers 1235/ 1050/1060/1070/1100 aluminum foil for you. Learn more.

application

Aluminum foil battery is is used as a current collector for lithium-ion batteries. Haomei offers 1235/ 1050/1060/1070/1100 aluminum foil for you. Learn more.

application

-

Aluminum Foil Paper for Cigarette Packaging

The aluminum foil thickness for cigarette packaging is 0.006mm to 0.007mm. The common alloys are 8011 and 8079. Learn more.

application

The aluminum foil thickness for cigarette packaging is 0.006mm to 0.007mm. The common alloys are 8011 and 8079. Learn more.

application

Latest Blog

-

In modern life, air conditioners have become an indispensable household appliance, creating a comfortable indoor environment for people. Aircon aluminum foil plays a vital role behind the efficient operation of air conditioners. Aluminum foil, with i

Blog

In modern life, air conditioners have become an indispensable household appliance, creating a comfortable indoor environment for people. Aircon aluminum foil plays a vital role behind the efficient operation of air conditioners. Aluminum foil, with i

Blog

-

Is Aluminum Foil Biodegradable

In today's era of increasing environmental awareness, we are increasingly concerned about the sustainability of the materials we use in daily life. Can aluminum foil, a material commonly used in kitchens, food packaging and industrial applications, be

Blog

In today's era of increasing environmental awareness, we are increasingly concerned about the sustainability of the materials we use in daily life. Can aluminum foil, a material commonly used in kitchens, food packaging and industrial applications, be

Blog

-

What Are 8011 Aluminium Foil Applications?

8011 aluminum foil is a metal foil made of aluminum as the main raw material through a series of rolling processes. With good formability, barrier properties and economic cost advantages, it has been widely used in packaging, air conditioning, household a

Blog

8011 aluminum foil is a metal foil made of aluminum as the main raw material through a series of rolling processes. With good formability, barrier properties and economic cost advantages, it has been widely used in packaging, air conditioning, household a

Blog

-

In the field of aluminum processing, the two pure aluminum foils 1100 and 1235 have formed differentiated application scenarios with their different composition designs and process characteristics.1. The essential difference between alloy composition and

Blog

In the field of aluminum processing, the two pure aluminum foils 1100 and 1235 have formed differentiated application scenarios with their different composition designs and process characteristics.1. The essential difference between alloy composition and

Blog

-

What Is Heavy Duty Aluminum Foil Thickness

In the family of material science, aluminum foil stands out for its unique properties and is widely used in many fields. Aluminum foil can be divided into light, standard and heavy according to thickness.Thickness definition of heavy aluminum foilGen

Blog

In the family of material science, aluminum foil stands out for its unique properties and is widely used in many fields. Aluminum foil can be divided into light, standard and heavy according to thickness.Thickness definition of heavy aluminum foilGen

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China