What Are Influencing Factors of Aluminum Sealing Foil Performance

For aluminum foil pharmaceutical packaging, the quality is largely reflected in the heat seal strength of the heat sealing aluminum foil. What are the influencing factors? The aluminum foil surface quality is very important.

For aluminum foil pharmaceutical packaging, the quality is largely reflected in the heat seal strength of the heat sealing aluminum foil. Therefore it is necessary to analyze the factors that affect the heat-sealing strength of aluminum foil pharmaceutical packaging.

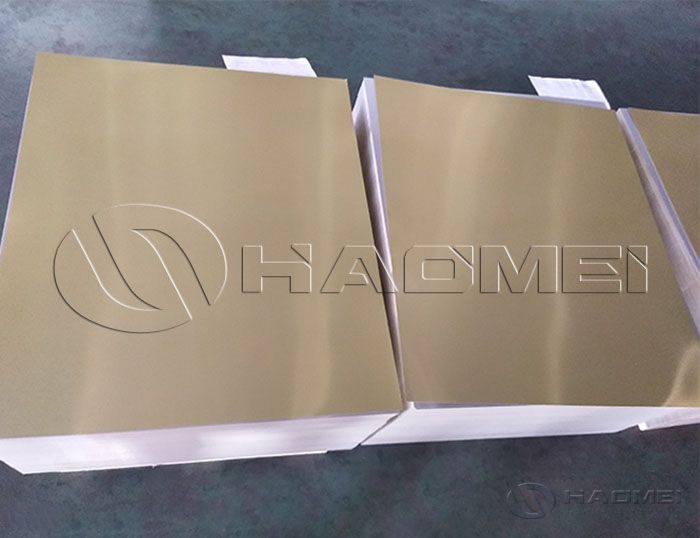

The aluminum foil is the carrier of the adhesive layer, and its quality has a great influence on the heat sealing strength of the product. Especially the surface oil of the original aluminum foil can weaken the bonding force between the adhesive and the original aluminum foil. If there is oil on the surface of the aluminum foil and the surface tension is lower than 31×10 m, it will be difficult to achieve the ideal heat sealing strength, so the quality of the original aluminum foil must be strictly controlled.

The adhesive is a special substance containing a solvent. It is coated on the dark side (or smooth side) of the original aluminum foil under certain process conditions, and is dried in an oven to form an adhesive layer, which plays a decisive role in the heat-sealing strength of the product. Adhesives can be divided into colorless transparent, gold and colored series.

The main process is to coat the adhesive on the surface of the original aluminum foil to form a film under the control of certain process parameters. The quality of the film can directly affect the heat-sealing strength of the product. The more important parameters include the speed of coating, the segmental temperature of the drying tunnel, the anilox shape, depth, number of lines of the coating roller, and the position and angle of the scraper.

The heat sealing temperature is an important factor affecting the strength of the heat seal. If the temperature is too low, the adhesive layer cannot be well heat-sealed with the PVC film, and the bonding between the adhesive layer and the PVC film will not be firm. If the temperature is too high, it will affect the medicine. Therefore, a reasonable heat-sealing temperature is usually between 150°C and 160°C.

To achieve the ideal heat sealing strength, it is necessary to set a certain heat sealing pressure. If the pressure is insufficient, not only the adhesive layer of the product cannot be fully attached to the PVC film for heat sealing, but even air bubbles will exist between the two, failing to achieve a good heat sealing effect.

The heat sealing time will also affect the heat seal strength of the product. Usually, under the same heat-sealing temperature and pressure, a longer heat-sealing time can make the heat-sealing part more firm and perfect, and can better achieve the expected heat-sealing strength. However, the process conditions of modern high-speed pharmaceutical packaging machines cannot provide a long time for heat sealing. If the heat sealing time is too short, the heat seal between the adhesive layer and the PVC film will be insufficient. For this reason, the national standard stipulates that the scientific heat sealing time is 1S.

In general, there are many factors that affect the heat seal strength of seal aluminum foil for pharmaceutical packaging. As a aluminum foil jumbo roll manufacturer, Haomei Aluminum can provide qualified aluminum foil jumbo roll like 8011 for heat sealing.

Inquiry

Products Category

Latest Application

-

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

Why butter aluminum foil is neededButter aluminum foil blocks oxygen, moisture, and light, effectively preventing butter from oxidizing and spoiling, preserving nutrients, and significantly extending its shelf life. High-end products can see their sh

application

-

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

Cables are usually composed of conductors, insulation layers, shielding layers, and sheaths. Aluminum foil for cable is generally located outside the insulation layer as part of the shielding layer. It fits tightly to the surface of the insulation la

application

-

Aluminum Gold Foil Paper For Chocolate Wrapping

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

When is aluminum foil used for chocolate wrappingThe use of aluminium foil food for chocolate can be traced back to the early 20th century. In 1911, Swiss candy companies began to wrap chocolate with aluminum foil, gradually replacing the tin foil. T

application

-

PVC Rigid Film and Aluminum Foil for Medicine Packaging

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

Haomei Aluminum provides different types of aluminum foil and plastic rigid films like PTP aluminum foil, cold forming foil, tropical foil, PVC rigid film, PE/PET film,etc. Best Price! Inquire now.

application

-

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Haomei Aluminum offers you different colors of air conditioner aluminum foil like hydrophilic aluminum foil, including1100/ 3003 /8006/8011 aluminum foil,etc. Learn more.

application

Latest Blog

-

Price Comparison Of Different Types Of Aluminum Foils

Aluminum foil jumbo roll is a versatile metallic material used in life, industry and medicine. Learn about the price ranges of household, air conditioning and pharmaceutical-grade aluminum foil, and the key factors causing their price differences.

Blog

Aluminum foil jumbo roll is a versatile metallic material used in life, industry and medicine. Learn about the price ranges of household, air conditioning and pharmaceutical-grade aluminum foil, and the key factors causing their price differences.

Blog

-

Aluminum Foil Specification for Food Container

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

Container aluminum foil for trays and pans: learn alloy choices, tempers, thickness, coatings, forming performance, and quality checks for stable production.

Blog

-

2026 China Aluminum Foil Export Price Forecast

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

2026 China aluminum foil jumbo roll export price forecast: Overall fluctuation with range-bound operation ($4100-$4400/ton), analyzing core supports, constraints & variables, offering references for industry practitioners & foreign trade enterprises.

Blog

-

Blister Aluminium Foil Base For Pharmaceutical Packaging

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

Learn how uncoated PTP aluminum foil becomes pharmaceutical-grade blister packaging. Explore surface pretreatment, coating processes, quality control & safety for medicine protection.

Blog

-

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Hot FAQs on 1235 aluminum foil: composition, common uses, thickness, pricing factors, and QC tests for packaging, tape, and battery-related needs.

Blog

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumfoils.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China